ADVERTISEMENTS:

This article throws light upon the four processes of waste water treatment.

The four processes are: (1) Preliminary Treatment (2) Primary Treatment (3) Secondary or Biological Treatment and (4) Tertiary or Advanced Treatment.

1. Preliminary Treatment:

As already stated, preliminary treatment involves the removal of floating materials (leaves, papers, rags) and settleable inorganic solids (sand, grit), besides oily substances (fats, oils, greases). The three major types of equipment-screeners, grit chambers, and skimming tanks, employed in preliminary screening are briefly described.

Screeners:

ADVERTISEMENTS:

A screener is a device with openings (usually uniform in size) to remove the floating materials and suspended particles. The process of screening can be carried out by passing sewage through different types of screeners (with different pore sizes).

The screeners are classified as coarse, medium or fine, depending on the size of the openings. The coarse screen has larger openings (75-150 mm). The openings for medium and fine screens respectively are 20-50 mm and less than 20 mm. Different types of screens-fixed bar screen (coarse or medium) disc type fine screen, drum type fine screen are in use.

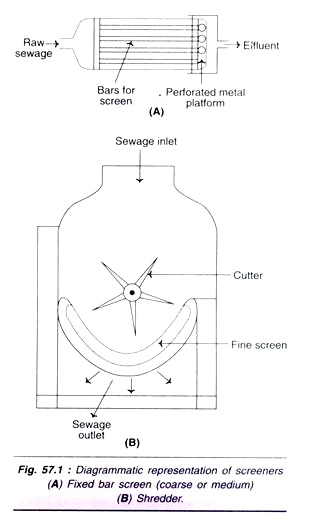

A diagrammatic representation of a fixed bar screen is shown in Fig. 57.1A.

A shredder or comminatory is a special screen that can cut and retain the floating and suspended materials (Fig. 57.1B).

Grit Chambers:

ADVERTISEMENTS:

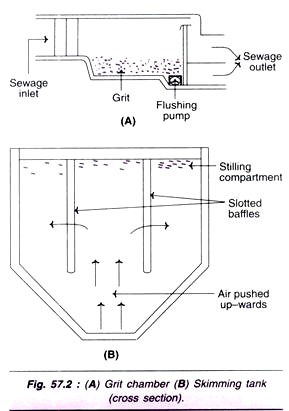

The heavy inorganic materials (specific gravity 2.4-2.7) like sand, ash and others can be removed by using grit chambers. This technique is based on the process of sedimentation due to gravitational forces. Grit chambers may be kept either before or after the screens. A diagrammatic representation of a typical grit chamber is depicted in Fig. 57.2A.

Skimming Tanks:

Several greasy and oily materials (fats, oils, waxes, soaps etc.) from the domestic or industrial outlets find their entry into the sewage. They can be removed by using a skimming tank which is fitted with baffle walls that divide the tank (Fig. 57.2B). The skimming tank is divided into three compartments that are interconnected.

As the compressed air is pushed from the floor of the tank, the raising air bubbles coagulate and solidify the oily and greasy materials present in the sewage. This material is pushed to the side compartment referred to as stilling compartment from where it can be removed manually or mechanically.

2. Primary Treatment:

Primary treatment is aimed at the removal of fine suspended organic solids that cannot be removed in the preliminary treatment. Primary treatment basically involves the process of sedimentation or settling. In the normal process of sewage treatment, sedimentation is usually carried out twice-once before the secondary treatment, referred to as primary sedimentation, and then after the secondary treatment is complete, a process known as secondary sedimentation. It is sometimes necessary to use chemical coagulants to facilitate or aid sedimentation, and this process is referred to as chemical precipitation or coagulation-aided sedimentation.

Principle of Sedimentation:

The solid particle of the sewage tend to settle down due to gravity. However, most of the solid particles of organic compounds remain in a suspended state in a flowing sewage. If the flow of the sewage is stopped and if it is stored in a tank referred to as sedimentation tank, the solid particles can settle down at the bottom. The process of sedimentation is influenced by several factors. These include the size, shape and specific gravity of particles, besides viscosity and flow velocity of sewage.

Types of Settling:

There are four major types of settling—discrete settling, flocculent settling, hindered or zone settling and compression. This categorization is mainly based on the tendency of the particles to interact and form solids.

Discrete settling:

ADVERTISEMENTS:

The particles which do not change their size, shape and weight are referred to as discrete particles or granular particles. The use of grit in sewage may be considered as an example of discrete settling.

Flocculent settling:

The flocculent particles can change their size, shape and weight, and thus lose their identity. These particles actually coalesce during settling. Settling of bioflocs, and chemical . floes in secondary sedimentation tanks are good examples of flocculent settling.

Hindered or zone settling:

ADVERTISEMENTS:

The particles as such, tend to remain in a fixed position with respect to each other. When flocculated, the whole mass of particles settle as a unit or a zone. In the hindered settling the concentration of particles increases from top to the bottom and this results in the thickening of the sludge. Zone settling is employed in conjunction with biological treatment facilities.

Compression:

Settlement of particles in the lower layers can occur by compression of the weight of the particles on the upper layers. This process facilitates sludge thickening at the bottom.

Types of Sedimentation Tanks (Clarifiers):

ADVERTISEMENTS:

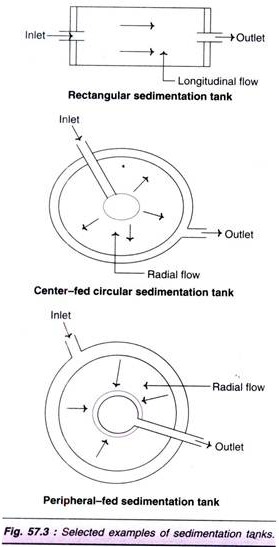

There are different ways of classifying sedimentation tanks.

Based on the shape:

Rectangular, circular and square.

Based on the flow of sewage:

ADVERTISEMENTS:

Longitudinal, vertical, radial and spiral.

Based on the purpose and position:

Primary, secondary, coagulation-cum-sedimentation tanks, grit chambers, septic and Imhoff tanks.

Based on the operation:

Batch type and continuous flow type.

For the sake of illustration, some sedimentation tanks are depicted in Fig. 57.3.

Chemical-aided Sedimentation:

It is not always possible to remove the colloidal wastes in sewage by plain sedimentation. However, addition of certain chemicals aids sedimentation, a process referred to as chemical precipitation or chemical-aided sedimentation. By this technique, about 60-80% of the suspended particles can be removed. Chemical precipitation involves three stages—coagulation, flocculation and sedimentation.

Coagulation is mainly a chemical process wherein the charged particles are destabilized (by the addition of chemical agents). On the other hand, flocculation involves the physical phenomena of aggregating the destabilized particles to finally form settleable solids (i.e. sedimentation). The chemicals used in chemical-aided sedimentation are of two types-coagulants and coagulant aids.

Coagulants:

These are the chemicals (normally positively charged) which form insoluble and gelatinous precipitates with colloidal particles (negatively charged ones present in sewage). The most commonly used coagulants in sewage treatment are alum (alluminium sulfate) iron salts (ferric sulfate, ferrous sulfate, ferric chloride), lime and soda ash (sodium carbonate), sodium silicate and sodium aluminate.

Coagulant-aids:

These chemicals aid or facilitate the process of coagulation. This is brought out by en-chancing the action of coagulants and reducing the amount of sludge formed. The common coagulant aids are activated silica, weighting agents (e.g. powdered lime stone or silica) and polyelectrolytes.

3. Secondary or Biological Treatment:

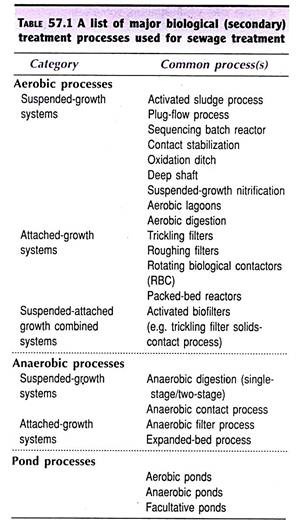

Biological treatment of sewage is required for the removal of dissolved and fine colloidal organic matter. This process involves the use of microorganisms (bacteria, algae, fungi, protozoa, rotifers, nematodes) that decompose the unstable organic matter to stable inorganic forms.

ADVERTISEMENTS:

The biological treatment processes of sewage are broadly classified as aerobic, anaerobic and pond processes. Depending on the nature of the use of the microorganisms, the biological processes are categorized as suspended growth systems and attached growth systems. A list of the major secondary (biological) treatment processes is given in Table 57.1, and the most important ones are briefly described.

Aerobic Suspended-Growth Treatment Processes:

The most important suspended-growth biological treatment systems used for the removal of organic matter are listed:

i. Activated sludge process

ii. Aerated lagoons

iii. Sequencing batch reactor

iv. Aerobic digestion.

Among these, activated sludge process is the most widely used for the secondary treatment of sewage.

Activated Sludge Process:

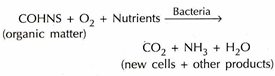

The activated sludge process, first developed in England in 1914, continues to be the most commonly used modern process for the biological treatment of sewage. In this method, the sewage containing organic matter with the microorganisms is aerated (by a mechanical aerator) in an aeration tank. The reactor contents are referred to as mixed liquor. Under aerobic conditions, the microorganisms metabolize the soluble and suspended organic matter. The generalized metabolic reaction is as follows.

A part of the organic matter is utilized for the synthesis of new bacterial cells while the remaining gets oxidized to CO2 and H2O. The newly formed microorganisms are agglomerated to form floes, technically referred to as sludge.

The separated sludge which is not in contact with organic matter becomes activated. It is separated from the settling tank, and returned to the aeration tank, and recycled. The activated sludge recycled in aeration tank serves as a seed or inoculum. The excess and waste sludge can be removed.

For efficient operation of activated sludge process, it is necessary to maintain a constant supply of O2 which can be done by mechanical aeration or through the use of rotating paddles. Growth of protozoa in a sludge is an indication of its healthy condition. The disposal of a waste sludge is a problem. It may be used as a fertilizer in crop lands or as landfills, after drying.

Factors affecting performance:

There are several factors that influence the efficiency of activated sludge process, the most important being the type of the reactor, aeration, food microorganism (F/M) ratio, nutrients, sludge recirculation rate, besides pH and temperature.

Advantages:

The activated sludge process is a very compact, low-cost and an efficient biological treatment system for sewage treatment. It is worked out that under ideal conditions, up to 95% of BODs, 98% of bacteria (particularly coliform) and 95% of suspended solids can removed by activated sludge process. The excess and waste sludge has a higher fertilizer value compared to other treatment processes.

Disadvantages:

There is production of large volumes of sludge which sometimes becomes difficult to handle. Power consumption is relatively high for operation. Supervision by skilled personnel is necessary.

Conventional activated sludge process:

In the normal treatment of sewage, the activated sludge is proceeded by primary sedimentation tank. The conventional activated sludge system consists of a separation tank, settling or sedimentation tank and sludge removal line (Fig. 57.4). The sewage after the primary treatment is introduced at the head of the tank. It is desirable to supply O2 uniformly throughout the tank.

Modified activated sludge processes:

For increasing the performance of the activated sludge system, several modifications have been done in the recent years. Most of them are directed to bring out efficient aeration. Aeration can be done by step aeration, tapered aeration, and high rate aeration by complete mixing and extended aeration.

Aerated Lagoons:

Aerated lagoons, also called as aerated ponds, are the facultative stabilization ponds wherein surface aerators are installed to overcome the bad adours (due to overload of organic materials). The microbiological treatment of aerated ponds is comparable to the activated sludge process. The major difference is the large surface area in aerated ponds and this is more susceptible for temperature effects. It is possible to carry out continuous nitrification in aerated lagoons. This however, depends on the design and operating conditions of the pond (particularly the temperature).

Sequencing Batch Reactor:

Sequencing batch reactor (SBR) is a modification of activated sludge treatment system. The processes namely aeration and sedimentation are carried out in both the systems. The major difference is that while in the conventional activated sludge system, aeration and sedimentation occur simultaneously in separate tanks, these two processes are carried out sequentially in the same tank in SBR. Thus, the sequencing batch reactor may be regarded as fill- and-draw activated sludge process.

The operating sequence of a typical SBR is depicted in Fig. 57.5. The process is carried out in a sequence of five steps — filling, aeration (reacting) sedimentation (settling), decanting and idle. Several modifications and improvements have been made in the SBR for more efficient operation.

Aerobic Digestion:

The organic sludge’s produced from various treatment processes (activated sludge treatment, trickling filter-sludge) are subjected to aerobic digestion in special reactors referred to as aerobic digesters.

Aerobic Attached — Growth Treatment Processes:

Aerobic attached-growth treatment processes are commonly used to remove the organic matter found in the sewage. These processes are also useful for the nitrification (conversion of ammonia to nitrate).

The commonly used attached-growth processes are listed:

i. Trickling filters

ii. Roughing filters

iii. Rotating biological contractors

iv. Packed bed reactors.

Among these, trickling filter is most widely used.

Trickling Filters:

Trickling filters, also known as percolating or sprinkling filters, are commonly used for the biological treatment of domestic sewage and industrial waste water. In a strict sense, trickling filters are not filters, but they are oxidation units.

A diagrammatic representation of trickling filter is depicted in Fig. 57.6. It has a bed of course, hard and porous material over which sewage is sprayed. In about two weeks time, the biomass attached to the media surface grows and forms a layer, referred to as biological film or microbial slime.

This film has a thickness of 0.1 to 2.0 mm and is rich in microorganisms. As the liquid (sewage) trickles through the biofilm, the organic matter gets oxidized to CO2 and NO2 by the microbial metabolism. This oxidation is carried out by the aerobic organisms (particularly bacteria) that are present on the upper portion of the biological film.

The biological film is rich in the bacteria- Pseudomonas, Flavobacterium, Alcaligenes, and algae-Chlorella, Utothrix, and Stigeoclonium, besides some fungi and yeasts. Biofilms with a thickness in the range of 70-100µm are efficient for the treatment process.

As the biofilm ages, its thickness increases and it automatically settles to the bottom of the tank. The waste waters obtained in milk processing, paper mills and pharmaceutical industries are treated by trickling filters.

Types of trickling filters:

The trickling filters are classified as low rate (the conventional one), high rate and super rate. This categorization is mainly based on the hydraulic and organic loading rates of the sewage. The low rate filters are suitable for the treatment of domestic sewage, while high rate filters and super rate filters are useful for industrial sewage.

Factors affecting performance of trickling filters:

The type of the media and its depth, organic and hydraulic loading, filter staging, recirculation rate and flow distribution are the important factors that influence the performance of the trickling filters.

Advantages:

Trickling filters are simple, occupy less space and the operating costs are low. They operate efficiently in hot climate and thus are suitable for most developing countries (like India).

Disadvantages:

Removal of BOD is moderate (around 70%), and disposal of excess sludge is necessary. Primary sedimentation is required, since trickling filters cannot handle raw sewage.

Roughing Filters:

Roughing filters are a special type of trickling filters that are designed to operate at high hydraulic loading rates. These filters are mostly used to “reduce the organic matter in downstream processing, besides nitrification applications. Due to high hydraulic loading, there is a continuous sloughing of the biological film. In such a case, the unsettled filter effluent can be recycled, and this increases the efficiency of the treatment process. The retention time on the biofilm being less, organic materials that are not readily degradable remain unaffected.

Rotating Biological Contactors (RBC):

Rotating biological contactor (RBC) is a recent device for the biological treatment of sewage. It operates on the principle of aerobic attached- growth system operated on the moving media. RBC are suitable for the treatment of domestic and industrial sewage in small and medium towns.

A rotating biological contactor is composed of a series of closely spaced and light weight circular discs (Fig. 57.7). They are made up of inert materials such s polystyrene or polyvinyl chloride (PVC) or polyethylene. These discs are mounted on a horizontal shaft in a tank through which waste water flows. The shaft is rotated slowly (less than 10 revolutions per minute) by a low speed motor.

The discs of the shaft, referred to as bio discs, are partially (40-60%) submerged in sewage. As the bio discs are rotated, the biomass attached to them is alternately submerged in sewage. This enables the discs to pick up a thin layer of sewage, and then to oxidize the absorbed substrates. The un-oxidized substrates fall back into the sewage. And this process in repeated again and again by the rotating bio discs.

Rotating biological contractor is basically a film flow bioreactor. The microbial biofilm is built upon the partly submerged support medium containing bio discs. The RBC is very efficient for the removal of organic matter in the sewage (about 90% of BOD). As and when there is an excess growth of biomass, it has to be removed. This process can be carried in a similar fashion, as it is done for the trickling filter.

RBC are commonly used for the treatment of municipal waste water. In addition, they are widely used for the biological processing of industrial wastes, coming from several industries such as vegetables, pulp, meat and textiles.

Factors affecting performance of RBC:

The treatment process in RBC is influenced by rotation speed of shaft, waste water retention time, temperature, disc submergence, organic loading, media density, and number of stages.

Advantages:

RBC is compact and requires moderate energy input. It has high BOD removal efficiency.

Disadvantages:

Disposal of sludge formed is a major problem with RBC. The treatment process is frequently associated with odour formation. RBC operation requires skilled personnel.

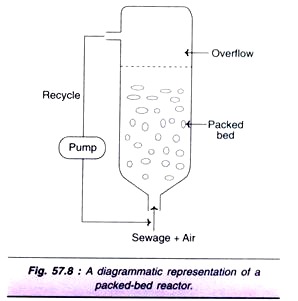

Packed-Bed Reactors:

Packed-bed reactors or fluidized bed reactors are used for the removal of BOD and nitrification. A reactor is packed with a medium to which the microorganisms get attached and form biofilms. The sewage along with air (or pure oxygen) is introduced from the bottom of the reactor (Fig. 57.8). The main advantage with packed bed reactors is that they have high surface area of biofilms for unit of reactor.

Anaerobic Suspended — Growth Treatment Processes:

Anaerobic processes basically involve the decomposition of organic and inorganic matter in the absence of oxygen. Anaerobic processing systems are important for the treatment of sludge’s, and high strength organic sewage. Several reactor systems for anaerobic suspended-growth treatment process have been developed. Among these, the complete-mix anaerobic digestion process is most widely used for the treatment of sewage.

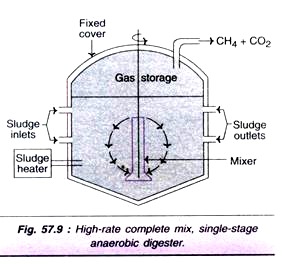

Anaerobic Digestion:

Anaerobic digestion is mostly useful for the stabilization of concentrated sludge’s that are produced on the treatment of industrial sewage. A diagrammatic representation of a typical high-rate, complete mix, and single stage digester is depicted in Fig. 57.9.

The process of anaerobic digestion is carried out in an air tight reactor. Sludge is introduced continuously or intermittently. In the high-rate digestion system, the contents of the digester are heated and mixed completely. And it takes about 15 days for the process to be complete.

Biodegradation of organic matter of sludge (or sewage):

The biological degradation of organic matter of sludge occurs in three stages (Fig. 57.10) — hydrolysis, acidogenesis and methanogenesis.

Hydrolysis:

In the enzyme-catalysed reactions, high molecular weight compounds (proteins, polysaccharides, lipids and nucleic acids) are degraded to low molecular weight compounds (amino acids, monosaccharide’s, fatty acids, purines and pyrimidine’s). The latter serve as substrates for energy supply and microbial growth.

Acidogenesis:

The low molecular weight compounds are converted to acidic products (propionate, butyrate, and lactate).

Methanogenesis:

This is the third and final stage and involves the production of methane and carbon dioxide, from the intermediates formed in acidogenesis. Methane gas is highly insoluble and its departure from the digester represents the stabilization of sewage or sludge.

Microorganisms to degrade organic matter of sludge (or sewage):

A consortium of anaerobic microorganisms work together for degradation of sludge (or sewage) organic matter.

They may be categorized into two types:

1. Acid-forming bacteria:

These are also known as acidogens or non-methanogenic bacteria. They bring out the hydrolysis of macromolecules (e.g. carbohydrate) to simple substrates (e.g. monosaccharide’s), and the latter to acids e.g. Clostridium sp, Corynebacterium sp, Lactobacillus sp, Actinomyces sp, Staphylococcus sp, Peptococcus anaerobus, Escherichia coli.

2. Methanogenic bacteria:

These bacteria, also referred to as methanogens or methane formers are responsible for the conversion of acetic acid and hydrogen to methane and carbon dioxide. The most important methanogens belong to the genera Methanobacterium, Methanobacillus, Methanococcus and Methanosarcina.

Anaerobic Contact Process:

Anaerobic contact process is carried out in a specially designed reactors. The treatment process consists of mixing of sewage with recycled sludge solids and then digestion under anaerobic conditions. After the digestion is complete, the supernatant effluent is discharged and the settled sludge is recycled. Anaerobic contact process is successfully used for efficient industrial wastes with high BOD e.g. meat packing wastes.

Anaerobic Attached — Growth Treatment Processes:

There are mainly two treatment processes under the anaerobic attached—growth treatment system— anaerobic filter process and expanded bed process.

Anaerobic Filter Process:

Anaerobic filter consists of a column filled with solid media for the treatment of organic matter in sewage. In this process system, waste water (sewage) flows upwards through the column containing anaerobic bacteria. Due to the presence of solid media, the bacteria are retained in the column. This makes the treatment process more efficient.

Expanded-Bed Process:

The sewage can be treated by pumping it through a bed of inert materials (sand or coal expanded aggregates) on which the bacteria have grown and formed a film. The effluent that comes out can be recycled to maintain the flow rate.

Pond Treatment Processes:

Pond treatment processes for the treatment of sewage (containing biodegradable wastes) are carried out by specially designed and constructed ponds. These ponds, referred to as stabilization ponds, are large, shallow earthen basins. The treatment process is a natural one involving the combined use of bacteria and algae. The stabilization ponds are classified as aerobic, anaerobic and facultative ponds.

Aerobic Ponds:

The aerobic ponds, as the name indicates, maintain complete aerobic conditions. These ponds usually have a depth of about 0.5 to 1.5 feet (150 to 450 mm) and allow the penetration of light throughout the liquid depth. A second type of aerobic ponds with a depth of 5 feet (1.5 m) are also in use.

In all these ponds, oxygen is maintained through continuous atmospheric diffusion (by surface aerators or pumps), besides the production by algae grown in the pond. The aerobic stabilization ponds contain bacteria and algae in suspension. They are particularly useful for the treatment of soluble wastes.

The algae and bacteria exhibit a symbiotic and cyclic relationship in the aerobic ponds. The algae can carry out photosynthesis and release oxygen to maintain aerobic conditions in the pond. The bacteria degrade the organic matter to produce CO2 and other nutrients to be utilized by algae (Fig. 57.11). Some higher organisms like protozoa and rotifers present in the pond are responsible for the polishing of the effluent.

Factors affecting aerobic ponds:

The species of the algae and bacteria present in the pond significantly influence the efficiency of the aerobic ponds. The other factors such as the quality and quantity of organic material, degree of pond mixing, nutrients, sunlight, pH and temperature are also important for the successful operation of these ponds.

Anaerobic Ponds:

Anaerobic ponds are useful for the treatment of high-strength organic matter and solid containing sewage/waste water. These ponds are completely devoid of dissolved O2. They are very deep (up to 30 feet i.e. about 9 m), so that heat conservation is possible, besides requiring minimum land area (for pond construction).

When the sewage is added to the pond, precipitation and anaerobic conversion of organic waste to CO2, methane and other gases, organic acids etc. occurs. Under suitable conditions, 75% of the BOD can be removed in anaerobic ponds. The clarified effluent is usually discharged for further treatment.

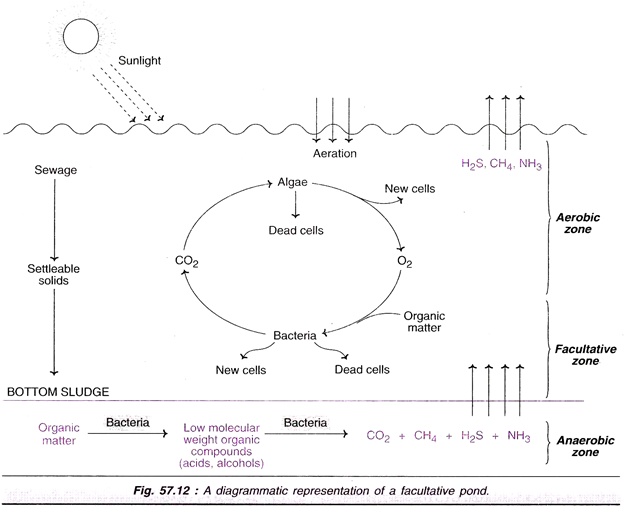

Facultative Ponds:

In facultative ponds, the treatment of sewage is carried out by a combination of both aerobic and anaerobic processes. Three types of microorganisms aerobic, anaerobic and facultative (both aerobic and anaerobic) are employed in facultative ponds.

The term oxidation pond or stabilization pond is frequently used for facultative ponds.

A diagrammatic view of a facultative pond is depicted in Fig. 57.12. It consists of three zones.

1. The surface aerobic zone:

It has the aerobic bacteria and algae, existing in a symbiotic relation

2. The bottom anaerobic zone:

It contains anaerobic bacteria and solids that undergo decomposition.

3. Intermediate facultative zone:

This zone is partly aerobic and partly anaerobic and contains both types (aerobic and anaerobic) of bacteria.

Processes that occur in facultative ponds:

The sewage organic matter is stabilized by both aerobic and anaerobic processes. The algae present in the aerobic zone carry out photosynthesis and release O2. This oxygen is utilized by the aerobic and facultative bacteria to oxidize soluble and colloidal organic matter.

The organic solids present in the anaerobic zone (bottom sludge) are degraded to dissolved organic compounds (organic acids) and gases such as CO2, CH4 and H2S. The organic acids can be oxidized by the aerobic bacteria while the gases produced (CO2, CH4, H2S, NH3) may be vented to the atmosphere. In fact, most of CO2 is utilized by the algae for photosynthesis, while H2S combines with O2 to form sulfuric acid.

H2S + 2O2 → H2SO4

In the absence of adequate O2 in the upper layers of the pond, gases with unpleasant and foul odours (H2S) are vented to the atmosphere. These foul smells often cause nuisance to the surroundings.

It is generally possible to maintain good O2 supply by the algae and facultative bacteria. Sometimes, surface aerators are used to enhance the efficiency of facultative ponds (particularly when the sewage contains high organic content).

Advantages:

For the facultative ponds, the initial and operating costs are low. There is no need for skilled personnel.

Disadvantages:

Unpleasant odours and mosquito breeding are frequently seen in facultative ponds. The requirement of land area for construction of these ponds is more.

4. Tertiary Treatment:

Tertiary treatment or advanced treatment is sometimes needed for the removal of suspended and dissolved substances, after the conventional primary and secondary treatments. In general, the effluent of the sewage obtained after secondary treatment can be conveniently disposed without causing any nuisance.

However, tertiary treatment is needed under the following circumstances:

i. When the quality of the effluent to be discharged does not meet the standard requirements (particularly in the developed countries).

ii. When there is a necessary to reuse the sewage/ waste water (reclamation of water is quite expensive, but is required in certain situations of water shortage).

iii. For the removal of nitrogen and phosphorus compounds.

Tertiary treatment process broadly involves the removal of suspended and dissolved solids, nitrogen, phosphorus and pathogenic organisms. In the conventional hierarchy of sewage treatment, the unit operations are carried out in the order of preliminary, primary, secondary and finally tertiary treatment.

However, sometimes advanced (tertiary) treatment process may be directly carried out bypassing the other unit operations. This mainly depends on the composition of waste water and the requirements.

There are four major processes under the tertiary treatment:

1. Solids removal

2. Biological nitrogen removal

3. Biological phosphorus removal

4. Disinfection.

Some authors use the term biological nutrient removal for the removal of nitrogen and phosphorus.

Solids Removal:

The techniques for the removal of suspended and dissolved solids in waste water treatment are comparable with those employed for the processing of potable (drinking) water.

Removal of suspended solids:

The effluents obtained from secondary treatment may contain suspended solids in the size 0.1 to 100µm. The concentration of these solids is variable, and is usually 20-40 mg/l. The removal of suspended solids is carried out by granular medium (sand) filtration and micro screening. Sometimes, diatomaceous earth filters and coagulation-cum sedimentation techniques are also used.

Removal of dissolved solids:

The dissolved solids can be removed mainly by two techniques—adsorption and ion-exchange.

Adsorption by activated carbon:

Activated carbon is highly porous and provides large surface area for the adsorption of dissolved solids in the advanced treatment. The compounds that can be removed by adsorption include organic materials (herbicides, pesticides, tannins, lignin’s, colour and odour producing substances), inorganic materials (toxic trace metals) and several other pollutants.

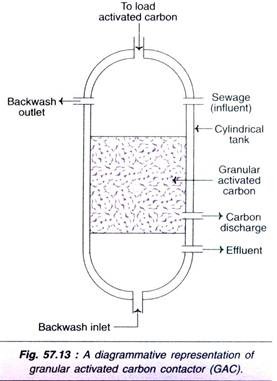

Granular activated carbon contactors:

Granular activated carbon contactors (GAC) are the most widely used for the advanced treatment of sewage. The GAC consists of a tank (usually cylindrical) which is loaded with granular activated carbon (Fig. 57.13). The waste water/sewage (influent) is passed from top through the activated carbon bed and the effluent comes out from the bottom. The solids attached to the carbon bed hamper further adsorption process. These particles can be removed by backwashing.

The activated carbon requires periodical regeneration. This can be done by heating in a furnace at about 800°C in the absence of O2. At this temperature; the adsorbed organic compounds are converted to gases and released. The carbon granulates are reactivated for reuse. Powdered activated carbon (PAC), instead of granulated carbon, is sometimes used for absorption process. PAC is added to an aeration tank (of secondary treatment) which can adsorb several organic compounds.

Ion-exchange for dissolved solids removal:

As the name indicates, ion-exchange involves the displacement of one ion by another. The exchange occurs between the ions of insoluble exchange material (ion-exchange materials) and the ions of different species in solution (i.e. waste water for advanced treatment).

The ion-exchange process is carried out by employing two types of ion-exchange materials— cation exchangers and anion exchangers (Fig. 57.14). The synthetic resins with strong acidic (H+) and basic (OH–) functional groups serve as ion exchangers. The cation exchangers (with H+ or Na+) can replace the positively charged ions (Ca2+, Mg2+) in water by hydrogen ions. This is what is done for removing the hardness of water.

The anion exchangers (with OH–) can remove negatively charged ions (SO42-, NO3, and CO32-). The waste water is first passed through a cation exchanger and then through an anion exchanger packed in two separate columns. When the ion exchange capacity of the resin is exhausted, it has to be regenerated for further use. For cation- exchange resins, regeneration can be done with strong acids (H2SO4, HCI), while for anion exchange resins, alkali (NaOH) is used. For an effective removal of dissolved solids by ion exchange, the waste water should not contain high concentration of suspended solids as they block the ion exchange beds.

Biological Nitrogen Removal:

Decomposition products of proteins and the urea present in sewage are the major constituents of biological nitrogen. Although, nitrogen is a nutrient, its excess concentration causes eutrophication, and thus its removal is required. Biological nitrogen removal (BNR) is carried out by the methods based on the following principles (Fig. 57.15).

1. Assimilation of nitrogen

2. Nitrification and de-nitrification.

Assimilation of nitrogen:

Since nitrogen is a nutrient, the microorganisms in the sewage can assimilate ammonia nitrogen, and grow. As some of these cells die, a portion of this ammonia nitrogen will be returned to the sewage.

Nitrification and de-nitrification:

Nitrification:

Ammonia nitrogen first gets oxidized to nitrite (NO–2) by the bacteria Nitrosomonas sp. This is followed by further oxidation nitrite (NO–2) to nitrate (NO–3) by Nitrobacter sp.

The bacteria involved in nitrification are auxotrophs. The nitrification process is accomplished by aerobic suspended growth and aerobic attached-growth systems. In the general practice, nitrification is carried out along with the BOD removal in the secondary treatment with suitable modifications. Trickling filters, rotating biological contactors and packed towers can be used for nitrification process.

De-nitrification:

The removal of nitrogen in the form of nitrate by converting to nitrogen gas is referred to as de-nitrification. This process occurs under anaerobic conditions and is brought out by certain genera of bacteria-Aerobacter, Bacillus, Brevibacterium, Lactobacillus, Micrococcus, Pseudomonas and Spirillum.

These bacteria are heterotrophs and require no oxygen, but the presence of organic carbon is essential. The presence of even minute quantities of O2 suppresses de-nitrification. The heterotrophic bacteria can reduce nitrate in the following stages, to finally nitrogen gas.

The process de-nitrification can be carried out by suspended growth and attached growth systems. The plug flow type of activated sludge system is commonly used. The flow diagram for the removal of biological nitrogen is depicted in Fig. 57.16. The process primarily consists of the removal of organic carbon (aerobic), followed by nitrification (aerobic) and de-nitrification (anaerobic).

Biological Phosphorus Removal:

Phosphorus in the sewage is mostly present in the form of orthophosphate (PO43-), polyphosphate (P2O7) and organic bound phosphorus. In fact, phosphorus is an essential nutrient for microorganisms. Thus, during the normal secondary treatment process, 10-30% of the sewage phosphorus is utilized by the microorganisms for growth and energy purposes. Phosphorus removal from waste water is required to control eutrophication and to maintain water quality.

Principle of phosphorus removal:

The biological removal of phosphorus is based on the principle of exposing the microorganisms to alternating anaerobic and aerobic conditions. When the microorganisms are subjected to anaerobic conditions, they release the phosphorus content and form a sludge which is deficient in phosphorus.

When this sludge (deficient in phosphorus) is returned to aerobic tank of sewage treatment, the microorganisms accumulate large quantities of phosphorus in their cells (as polyphosphates). These microorganisms when subjected to anaerobic conditions release the phosphorus and this cycle (of alternating anaerobic and aerobic processes) can be continued for the biological removal of phosphorus. Acinetobacter sp are mainly responsible for the biological removal of phosphorus.

The process of phosphorus removal:

Based on the principle described above, processing plants have been developed for the biological removal of phosphorus. Phostrip (phosphate stripper) process system, used for this purpose is depicted in Fig. 57.17. The anaerobic phosphate stripper removes the phosphate, and the resultant sludge is returned to aeration tank which takes large quantities of phosphorus. After sedimentation, the phosphorus enriched sludge again passes through Phostrip, and the cycle is repeated again and again.

The phosphorus enriched supernatant that comes out of the phosphorus stripper is treated with lime to precipitate the phosphorus. The resultant liquid supernatant can be returned to the aeration tank for further treatment.

Disinfection:

Disinfection broadly refers to the selective destruction or inactivation of disease-causing (pathogenic) organisms. In the process of disinfection, all the organisms are not destroyed. This is in contrast to sterilization which involves the destruction of all the organisms. There are several water borne diseases (typhoid, cholera, dysentery) caused by bacteria, viruses and other pathogens. The very purpose of disinfection is to control these diseases.

Agents for disinfection:

Disinfection is accomplished by using chemical and physical agents, besides mechanical and radiation means.

Chemical agents:

Chlorine and its compounds are most commonly used. The other chemicals— bromine, iodine, ozone, alcohols, phenols, heavy metals, hydrogen peroxide, alkalies and acids are sometimes employed. After chlorine (regarded as most universal disinfectant), bromine and iodine are in use. In recent years, ozone as a disinfectant is gaining importance, since it is very effective.

Physical agents:

Heat and light can be effectively used as disinfectants. Sunlight (particularly ultra-violet rays) is in fact a good disinfectant.

Mechanical means:

The pathogenic organisms can also be removed by mechanical means, during the course of waste water treatment. The processes involving screens (coarse and fine), grit chambers and sedimentation can partly remove the disease- causing organisms.

Radiation means:

The gamma rays emitted from radioisotopes can serve as effective disinfectants.

Characteristics of an ideal disinfectant:

An ideal disinfectant should possess the following characteristics:

i. Toxic to pathogens at low concentration

ii. Soluble and stable in water

iii. Non-toxic to man and higher organisms

iv. Cheap and easily available.

Disinfection with chlorine:

Chlorine is a very widely used disinfectant, as it satisfies the criteria of an ideal disinfectant. The most commonly used chlorine compounds are — chlorine gas (Cl2), calcium hypochloride [Ca(COCI2)], sodium hypochlorite (NaOCI) and chlorine dioxide (CIO2).

The disinfection efficiency of chlorine depends on the number of microorganisms in the water being treated, pH and temperature.

Sewage/Waste Water Treatment —A Summary:

A conventional sewage treatment plant has the requisite operating units arranged one after another for treatment and final disposal of sewage. The flow chart of a conventional sewage treatment plant is depicted in Fig. 57.18.