ADVERTISEMENTS:

In this article we will discuss about the methods and procedures to make bread in bakery. Learn about:- 1. Introduction to Bread Making 2. Methods of Bread Production 3. Functions of Yeast in Bread-Making.

Introduction to Bread Making:

Baked foods are produced and consumed in most of the countries of the world. Considerable variation exists in the type of baked foods that are made from country to country, and often among regions within a given country.

Some of the ways in which bread can vary are summarized as follows:

ADVERTISEMENTS:

Leavening:

Breads may be unleavened, such as chapatti; leavened with yeast, such as pan breads; chemically leavened, such as Irish soda bread; or leavened with bacteria, such as salt rising bread.

Formulation:

Many types of bread around the world are made with lean formulas comprising flour, water, yeast, and salt, while some bread, such as certain premium breads made in the United States, also contain considerable amounts of other ingredients such as fat, eggs, and milk.

ADVERTISEMENTS:

Shape and Size:

A virtually endless variety of shapes and sizes have evolved; some bread is baked in pans while many are baked on the oven hearth.

Specific Volume:

This factor can vary from the low-density, high-volume white pan breads made in North America to the dense, dark breads of Central Europe.

Crust Characteristics:

Some bread, such as Vienna loaves, has thin crispy crusts, while others, such as German pumpernickel breads, have thick crusts. Colors range from quite light to dark colors.

Crumb Characteristics:

Continuous mix breads in the United States have a very fine, uniform crumb structure, while other breads such as French baguettes have coarse, irregular structures. Some Middle East breads have little crumb structure at all, being comprised largely of crust because of the high baking temperatures that are used.

Means of producing these baked foods also vary considerably. Large, highly-mechanized bakeries account for much of the production in developed countries. In less developed countries, bakeries are typically quite small, and operations are conducted with the help of little, or at times no, mechanical equipment.

ADVERTISEMENTS:

A common denominator in many of these countries is that baked foods, bread in particular, have traditionally been an important factor in human nutrition. In some countries, bread consumption accounts for a large part of the diet.

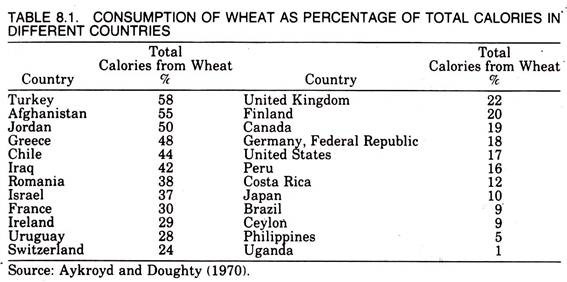

Aykroyd and Doughty (1970) compared the consumption of wheat in many countries. Part of their data is summarized in Table 8.1.

These figures indicate that in some countries over half of the total calories consumed come from wheat. Many of the developed countries appear to consume roughly 17 to 30% of their calories from wheat.

ADVERTISEMENTS:

While wheat is consumed in many forms (gruels, pasta products, stews, etc.) much of the wheat for human consumption is processed into flour which is then made into baked foods. This is especially true in the developed countries. For example- in the United Kingdom during 1974-1975, about 5 MT of wheat are milled yearly to give 3.6 MT of flour, the by-products such as bran and wheat germ are utilized as animal feed. Of this white flour, 67% is used in commercial bread-making, 11% in biscuit manufacture, 8% for household use, and 14% for miscellaneous usage.

Developed countries as well as many less developed countries have well organized baking industries that today produce much of the baked foods that are consumed.

The category of “other breads” is made up of wheat, rye, etc., and makes up about 21% of the total bread and roll market. However, it may be noted that the other, or variety, bread market is expanding substantially, in part due to expanded consumer interest in “natural” foods. It is expected that by 1980 about 30% of the bread market will be taken up by variety breads.

As with other major industries, there is a trend toward fewer but larger manufacturing establishments in the United States baking industry. From 1958 to 1972 there was a drop from about 6000 to about 3300 bakeries employing 20 or more persons.

ADVERTISEMENTS:

Most of the baked products are made in large wholesale bakeries; there were approximately 1100 wholesale plants having 50 or more employees in 1977. During that year, the largest 20 companies had sales of $4.7 billion of baked foods made in 342 plants; 5 companies had sales of $2.7 billion for products made in 207 plants.

Cereal products, largely in the form of bread, have an important role in the diet of many countries, including developed countries, although some of these are experiencing a slow decline in cereal consumption.

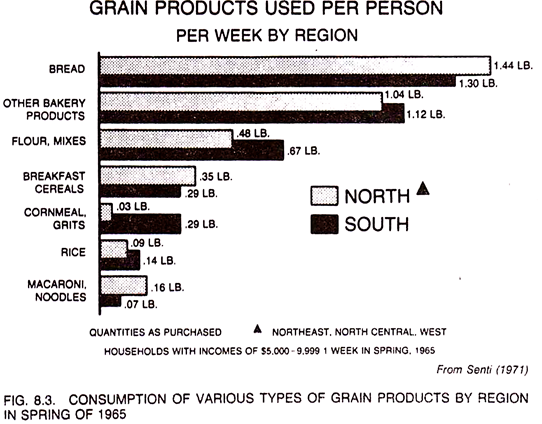

Senti (1971) summarized the contribution of grain products to the United States diet, using as his basis reports from over 7500 households in 1965. Fig. 8.2 shows that grain products provided 40% of thiamin intake, 31% of the iron, 26% of the food energy, 20% of the protein, and 19% of the riboflavin. The more important types of grain products consumed in the United States are given in Fig. 8.3 from a study in 1965.

These values indicate that bread and other bakery products comprise a large part of the grain products eaten. Some differences in consumption are noted between northern and southern households. Consumers in the South appear to purchase somewhat less bread, but more of other bakery products, flour, and mixes, and cornmeal and grits compared to northern households.

Enrichment plays a major role in the nutrient contribution of bread and other cereal foods. During the early 1940s, the baking and milling industries in cooperation with the medical profession and government agencies voluntarily adopted an enrichment program to restore B vitamins and iron to bread.

The enrichment program has continued to the present, and it is generally believed that enrichment has had a positive impact on the well- being of the country. Today virtually no incidence of beriberi or pellagra can be found, in marked contrast to the situation prior to initiation of enrichment. A major part of this improvement is credited to the enrichment program.

Present United States enrichment levels for 0.45 kg (1 lb) bread call for 1.8 mg thiamin, 1.1 mg riboflavin, 15.0 mg niacin, and 12.5 mg iron. Calcium may optionally be added to a level of 600 mg per 0.45 kg.

Enrichment in other countries varies considerably. Canada, Chile, El Salvador, and Mexico practice enrichment. In Europe, the United Kingdom and Sweden and Denmark enrich bread, but other countries do not; France essentially prohibits the practice. Japan enriches flour for its national school lunch program, and also markets “special enriched” wheat products.

ADVERTISEMENTS:

Methods of Bread Production:

The type of bread most widely produced and consumed in the United States today is white pan bread.

This bread is made by a number of procedures, but the most common methods utilized are:

The sponge dough process was introduced during the 1920s and is today the predominant bread-making method used by the baking industry. The popularity of the sponge dough method is due, in part, to the greater processing tolerance of the procedure and to the flavor of the bread, generally regarded as superior compared to breads made by other methods.

A schematic diagram of the sponge dough process is illustrated in Fig. 8.4, and Table 8.4 summarizes a typical formula used in white pan bread production.

The “sponge,” comprising about 65% of the total flour plus a portion of the total dough water, yeast, and “yeast food,” is first mixed. This mixing period is relatively brief, and merely aims at uniformly combining the sponge ingredients. The sponge is then discharged into a trough, where it will undergo a fermentation period of some 4.5 hr in a controlled environment.

From a starting temperature of about 25°C, the final temperature will increase by approximately 6°C due to the exothermic reactions brought about by yeast activity. Sponge volume will also increase by a factor of 4 or 5 as a consequence of carbon dioxide production during fermentation.

At the end of sponge fermentation, the sponge is transferred into a dough mixer. The balance of the flour is also placed into the mixer, along with the water and remaining ingredients. The mixer is operated first slowly to incorporate and blend these components, then the mixer is speeded up (typically the mixer arms rotate at about 72 rpm) until the dough is completely mixed and properly “developed.”

At this point, the dough has been transformed from a sticky, wet-appearing mixture into smooth, cohesive dough, characterized by a glossy sheen. This change occurs because of the unique properties of wheat flour. Upon the addition of water and the input of energy, wheat proteins and lipids form gluten.

Gluten comprises the continuous phase of dough, and possesses film-forming and gas-retaining properties. As Saccharomyces cerevisiae evolves carbon dioxide, this gas diffuses into previously-formed gas vesicles; the dough, due to the unique nature of gluten, is able to retain this gas and is thereby leavened.

The mixed dough is placed in troughs and allowed to rest for 20 to 30 min. During this period, the dough recovers from mechanical stress; it relaxes, and is better able to undergo the remaining processing stages.

Dividing the dough is the next stage. During this stage, the dough is cut into pieces of desired weight by a machine that volumetrically divides the pieces and discharges them onto a moving belt. The dough pieces are conveyed to a rounder, where the rough-appearing pieces are forced along a metal sleeve such that the pieces become rounded and have a smooth, dry skin. In this condition, the dough pieces retain more carbon dioxide and are less sticky.

The dividing and rounding operations impose a certain amount of stress to the dough pieces, with the result that they are somewhat degassed and unpliable. To compensate for this effect, the dough pieces upon leaving the rounder are accorded another rest period, or intermediate “proof,” of some 8 to 12 min. This takes place in tray-type conveyors enclosed within cabinets of different configurations.

From the intermediate proofer, the dough pieces are conveyed to molding machines, which transform the more-or-less round pieces of dough into cylinders. Molders perform their functions with a series of rollers which sequentially squeeze the dough piece into a sheet, curl the sheet into a cylinder, and finally roll and seal the cylinder. Automatic molders feed the dough cylinders into bread pans.

Pans containing the dough pieces are placed in fermentation units called proof boxes for the last fermentation period prior to baking. The environment in these units is typically maintained at 35° to 43°C at a relative humidity of 80 to 95%. The dough pieces expand in the pans to a desired volume, a process usually requiring approximately 60 min. The proofed loaves are then placed in an oven for baking.

Gas within the dough fabric expands and the “oven spring” is produced. Steam and alcohol vapors also contribute to this expansion. Enzymes are active until the bread reaches about 75°C. At this temperature the starch gelatinizes and the dough structure is “set.” When the bread surface temperature reaches 130° to 140°C, sugars and soluble proteins react chemically to produce an attractive crust color. The center of the loaf does not exceed 100°C.

Remaining stages in the bread-making process include cooling of the baked bread, slicing, wrapping, and distribution to stores for sale to the consumer.

All of the ingredients for the straight dough are combined and mixed in one operation. After mixing, the straight dough is given a bulk fermentation period of 2 to 4 hr and is then processed in a manner similar to that described for the doughs in the sponge dough process.

Straight doughs require less labor, time, and equipment compared to sponge doughs, but, exhibit less tolerance to processing variations. This factor, plus the characteristically blander flavor of straight dough bread, has led over the years to the commercial preference of sponge doughs over straight doughs. Today, straight doughs are used mostly by smaller bakeries or for specialty bread production by larger bakers.

Continuous bread-making technology was introduced in the United States during the 1950s. In common with other industries, the baking industry sought to lower production costs and increase product uniformity by means of continuous processing. The Do-Maker process and the Amflow method are the continuous mix processes used in the United States.

This method and the Do-Maker method share essential features.

Initially a ferment or brew (stage 1) is made (with or without some flour in the case of the Do-Maker), and this is fermented in a holding tank for about 1 hr. A second stage (water, salt, and sugar) is added to the system, and fermentation continues for a total of about 2.5 hr. At the end of fermentation the brew is pumped to a pre-mixer; cooling of the brew is achieved by means of a heat exchanger.

The remaining flour and water, sugar, melted fat, oxidant, and other optional ingredients are also fed into the pre-mixer. After the pre-mixer combines all of these ingredients, the loosely mixed mass is pumped to a developing chamber. This chamber contains 2 counter rotating arc impellers. As the dough passes through the chamber it is under pressure and is subjected to intense mechanical energy.

Under these conditions the dough is quickly developed and is then extruded into pans from a slit in the bottom of the chamber by a system of intermittently actuated knives. The dough from the continuous mix developer is much softer and warmer (about 38°C) compared to sponge doughs. The dough pieces are proofed and baked in a manner similar to that of sponge doughs.

Continuous mix breads differ from “conventional” breads. They have a much finer, more fragile crumb structure. These factors coupled with a flavor that some consumers feel is less desirable than that of sponge dough bread have limited the acceptance of continuous mix bread in some markets.

Procedures for making bread employing liquid or semi-liquid ferments have been known for many years. Advances in equipment design stemming from continuous mix technology made the utilization of liquid ferment bread-making systems more feasible. Such systems combine standard equipment to mix and process doughs with pumps and tanks to handle liquid brews. Advantages often cited for liquid ferment systems compared to traditional bread-making procedures include (1) savings in plant space, (2) labor savings, (3) more processing flexibility, and (4) improved sanitation.

In this system, a liquid ferment or brew is prepared and allowed to undergo fermentation much as described for continuous mix operations. After fermentation, the brew is pumped to a dough mixer (same type as used in conventional sponge dough processing), along with remaining ingredients. The dough is mixed and then subjected to the same processing steps as outlined for the dough in the sponge dough process.

Functions of Yeast in Bread-Making:

Yeast obviously has an irreplaceable role in bread-making.

At least 3 major functions of yeast in bread-making can be recognized:

(1) Leavening:

Yeast gives off carbon dioxide gas due to its metabolism of simple sugars. In bread-making, Saccharomyces cerevisiae utilizes sugars derived from flour, and/or sugars added as a component of the dough formula.

During fermentation in the sponge of the traditional sponge dough process, the only source of fermentable carbohydrate for the yeast is that obtained from the flour. Early in the fermentation carbon dioxide is evolved rapidly as S. cerevisiae utilizes the available free sugars from the flour. A sharp drop-off in the rate of carbon dioxide production occurs after about 1 hr or so when the free sugars are depleted.

At this point the yeast adapts to the fermentation of maltose, and gas production again rises. Maltose becomes available as a result of amylase hydrolysis of a part of the flour starch that has been mechanically damaged during milling. At the end of about 3 hr this source of fermentable sugar is exhausted and gas production drops off.

Added Sweetener:

During the dough stage of sponge dough processing and in straight doughs or other bread making systems where all ingredients are present, S. cerevisiae will utilize sweetener added to the dough as an ingredient. Glucose in commercial dextrose, and glucose and fructose contained in some corn sweetener systems will be directly utilized by yeast.

Added sucrose is almost immediately hydrolyzed into the constituent monosaccharides glucose and fructose due to the action of invertase. The yeast will then ferment both simple sugars, but at differing rates; glucose is preferred and is fermented at a faster rate than is fructose. Bread made with added sucrose typically will contain more fructose as a residual sugar than glucose. The relative rates of utilization of fructose, glucose, and maltose in dough are shown in Fig. 8.7.

Added Amylases:

Amylases are known to randomly split starch molecules into smaller units of varying size (α-amylase) and progressively release maltose from the terminal portion of starch molecules (β-amylase). These enzymes are important in providing fermentable sugars for yeast growth and gas production, and to improve handling and other properties of doughs. Amylase activity enhances the external surface color, volume, and keeping quality of bakery products.

Before wheat was harvested by heavily mechanized methods, uncontrolled germination of wheat and barley during wet crop years led to the accumulation of high levels of α-amylase. Un-germinated wheat and barley contain low levels of α-amylase. In contrast, β-amylase activity is substantial and changes little upon seed germination.

In order to elevate enzyme activity in flours milled from mechanically harvested cereal grains, malted wheat and barley have been traditionally added. More recently the addition of fungal o-amylase to flours at the mill or bakery has been practiced. The enzyme is derived from Aspergillus oryzae, A. niger, or A. awamori and is available in the form of diluted powders or water-dispersible tablets.

The influence and effects of fungal α-amylase supplementation on the development of desired quality of bread, rolls, buns, and crackers is numerous. Hydrolysis of dextrins yields maltose and glucose which sustains the fermentation rate and also produces additional sugar in the finished product. Fungal enzyme mixtures contain higher levels of glucoamylase than do cereal and bacterial amylase preparations.

This is important where sugars are not added to the formula and where the yeast has low maltase activity. α-Amylase activity lowers dough viscosity and affects dough softness. The relative fineness of the cells comprising bread crumb (i.e., the “grain”) and other yeast-leavened baked foods is influenced by the amount and type of a-amylase present in dough.

Consequences of Carbon Dioxide Production:

Evolution of carbon dioxide into the dough by the action of S. cercvisiae leads to the porosity of bread, a characteristic that undoubtedly has been a major factor in the acceptance of bread by many nations down through the years. This porosity is due to the carbon dioxide produced by the yeast and to the ability of the dough to retain the gas. The latter ability is related to the film-forming properties of dough made with wheat flour.

Gluten, the protein complex of dough, forms a continuous structure in which is an embedded starch granule; the gluten can be stretched into viscoelastic films that form the walls of gas cells. Carbon dioxide diffuses into these cells during the course of fermentation. The gas cells undergo subdivision during various dough-processing steps and eventually form the basic cellular or porous structure of bread.

The classic investigations of Baker and Mize (1941) indicate that carbon dioxide generated during yeast fermentation does not in itself produce gas cells. Yeast-generated carbon dioxide diffuses into cells already formed from two sources, viz., air bubbles occluded in the dough during mixing and air adsorbed on flour particles (one-fifth of the volume of flour is entrapped air).

(2) Flavor Development:

Fresh bread has a pleasing and appealing flavor that in part is responsible for its universal acceptance as a human food. Yet the flavor is subtle and difficult to characterize in spite of considerable effort to do so. A comprehensive review of this subject has recently been compiled.

Bread flavor is derived from two main sources- yeast fermentation and crust browning.

Yeast Fermentation:

The contribution of the flavor of baker’s yeast to bread flavor has rarely been considered, and is certainly not a major factor. Nevertheless, it is known that doughs made with high concentrations of yeast yield baked products with “yeasty” or slightly “cooked” flavors. Hohn et al. (1975) have found that thiamin and thiamin diphosphate are the major flavor compounds in yeast which may contribute to an undesirable flavor of the bread.

The characteristic flavor of yeast raised bread arises from yeast fermentation and subsequent reaction of fermentation products with other dough compounds during baking. The taste and odor of fermenting dough resemble that of fermenting beer wort and fermenting wine, and the flavor compounds which have been isolated are qualitatively the same.

During the baking some of these flavor compounds escape and others react with amino acids and other compounds of the dough to yield the characteristic flavor of bread. The fermentation by-products formed during yeast fermentation fall largely into the classes of organic esters and acids, alcohols, and carbonyl compounds. Attempts to synthesize bread flavor by combining compounds found in doughs, liquid ferments, or bread have not been successful.

Many observers feel that traditional methods of bread-making involving substantial periods of bulk fermentation yield bread with the most desirable flavor. A number of studies have been done showing that certain organic compounds do increase in concentration as a function of fermentation time.

Countering this view, however, is the work of other investigators which has shown that taste panel members could not distinguish flavor differences in bread made with or without bulk fermentation. These findings would indicate that flavor compounds formed during baking and during proofing were sufficient to yield satisfactory bread flavor.

It should be noted here that some of the organic compounds formed during fermentation may arise from bacterial action. Lactic acid bacteria found in dough presumably are associated with yeast; commercial bakers’ yeast normally contains a low number of contaminating microorganisms. In addition to S. cerevisiae, other yeasts may be responsible for characteristic flavors of certain breads.

The exact role of yeast fermentation in bread flavor development is not well understood. Yet, it would seem clear that yeast fermentation by-products must play an important role in bread flavor. Even if traditional bulk fermentation is not used in bread-making, the loaves must be proofed. During this period S. cerevisiae proliferates and produces compounds which undoubtedly contribute to flavor, either directly or as flavor precursors.

Breakdown products of flour protein undoubtedly play an important role in flavor and color development. Yeast proteolytic enzymes modify peptones and polypeptides for growth; however, a portion of these products react with sugars to impart desirable flavors upon baking.

Proteolytic enzymes are in fact added to doughs on a large commercial scale, and it is estimated that two-thirds of the white bread baked in the United States is treated with enzymes derived from Aspergillus oryzae. Proteolysis during the fermentation stage results in shortened protein chains which realign into sheets of protein film. As a result, less time is required before the point of maximum extensibility is reached.

Proper levels of fungal proteinase improve handling and machining properties of dough and yield bread loaves having increased volume and better symmetry.

Fungal and bacterial proteinases mellow the gluten during fermentation to yield the proper balance of extensibility and strength in cracker dough. These doughs can be rolled out very thin without tearing and lie flat in the oven without bubbling or curling at the edges.

Crust Browning:

The extent of crust browning is influenced substantially by previous activities of S. cerevisiae in the dough. The importance of crust browning in flavor development can be shown by removing the crust of freshly baked bread and storing the bread until it has cooled, or by baking bread in a microwave oven where crust browning does not occur.

Under these conditions the product will lack the flavor usually associated with bread. Presumably, therefore, a part of bread flavor is formed in the crust during baking and then diffuses into the crumb where it becomes absorbed. Over 100 flavor compounds have been found in bread.

Table 8.7 lists some of the compounds reportedly produced during fermentation and/or baking.

Yet another function of yeast is to cause many changes in dough that are often summarized as dough “maturing” or “ripening.” A properly matured dough is one that exhibits optimum rheological properties (optimum balance of extensibility and elasticity), such that it may be machined well and will lead to bread with desirable volume and crumb characteristics.

Some of the reactions leading to dough maturing are considered below:

Alcohol and carbon dioxide, among other products, are derived from yeast fermentation. Alcohol is water miscible and, since appreciable amounts are formed, it therefore influences the colloidal nature of the flour proteins and alters the interfacial tension within dough.

Some of the carbon dioxide dissolves in the aqueous phase of the dough and forms weakly ionizable carbonic acid, which lowers the pH of the system. Carbon dioxide also distends the dough as the gas expands, thereby contributing mechanical work into the dough system.

Ammonia from ammonium sulfate and ammonium chloride added to the dough as yeast foods” are assimilated by S. cerevisiae, causing liberation of sulfuric and hydrochloric acids. These acids along with carbonic acid further lower the pH which, in turn, significantly influences gluten hydration and swelling, the reaction rate of enzymes in dough, oxidation-reduction reactions, and various chemical reactions.

S. cerevisiae also produces reductases, which affect dough rheological properties by acting through intermediate substrates found in dough.

Bacterial Processes in the Production of Bread:

Sourdough bread in the United States is usually made from a mixture of rye and wheat flour containing up to 80% of wheat flour. The acid taste may be obtained by adding mixtures of lactic and acetic acids. Such breads are usually leavened with yeast, and the action of lactic acid bacteria (if it occurs) is only incidental.

In Europe and for some American rye sour breads the use of “sourdough starters” is preferred because it gives the full flavor which depends on the microbial souring action. The use of such rye sour cultures predates recorded history. It is relatively easy to produce such starter by mixing rye flour and water in equal proportions and permitting it to ferment for several days at 30°C. This forms the basis of the culture which can then be maintained by further additions of rye flour and water.

Sourdough starter cultures are also available commercially and these can be used to inoculate the doughs. Such cultures usually contain mixtures of lactic acid bacteria. Spicher and Shroder (1978) classified the organisms as subgroups of the genus Lactobacillus as follows – Thermobacterium (L. acidophilus), Streptobacterium (L. casei, L. plantarum, L. farciminis, L. ali- mentarius), and Betabacterium (L. brevis, L. buchneri, L. fermentum, L. fructivorans).

All of the strains isolated by these authors fermented maltose, about three-fourths fermented fructose, one-half fermented sucrose, and about one-fourth fermented lactose. Ordinary bakers’ yeast (S. cerevisiae) usually contains 10,000 to several million lactic acid forming bacteria per g, and its use will result in souring of the dough if the fermentation is carried out for prolonged periods of time and at relatively elevated temperatures.

The lactic acid bacteria usually found in sour rye fermentations are L, plantarum, L. brevis, and L. fermenti. Homofermentative bacteria producing only lactic acid are usually thermophiles and do not grow at the relatively low temperatures of dough fermentations. Homofermentative bacteria producing only acetic acid also do not find a favorable climate in the anaerobic doughs. Therefore, lactic and acetic acids are mainly produced by heterofermentative bacteria found in doughs.

Today bakers’ yeast is frequently added to sourdoughs to increase the leavening activity of the system. In spontaneous sourdoughs (to which no bakers’ yeast had been added) Spicher and Schollhammer (1977) found 4 types of yeasts. For 3 of these groups the yeasts could be identified as S. cerevisiae, Pichia saitoi, and Trichosporon penicillatum, respectively.

Yeasts in one of the groups could not be identified. The number of yeast cells in spontaneous sourdoughs was about 1.3 x 109 per g and that of bacterial cells from 4 to 6 x 109 per g. The growth of yeasts and bacteria in such doughs is illustrated in Fig. 8.16 together with the concomitant drop in pH and the increase in titrable acidity. For a description of sourdough processes see also Schulz (1962).

A white sourdough bread produced only in the western United States is the San Francisco sourdough bread. It is of special interest because it is still produced by propagation with sponges from the previous day’s production. The characteristic yeast of this process is Torulopsis holmii and the bacterium producing both lactic and acetic acids has been named Lactobacillus sanfrancisco. The sponges contain only water, flour, and the microorganisms and require about 8 hr at 25°C for full development. The final pH may be as low as 3.9. About 20% of the starter sponge is used in the dough (based on the weight of dough flour).

The Italian Pannetone is a traditional Christmas fruitcake which is also made from starter sponges. The characteristic yeast is identical with that of San Francisco sourdough. The dominant lactic acid producer was identified as L. brevis.

There is a considerable similarity between the bacteriological events in sourdough sponges and in cracker dough sponges. Cracker sponges ferment for about 18 hr before the doughs are made up, and a portion of the cracker sponge is often kept for inoculation of the next sponge. Very small percentages of bakers’ yeast are used (0.125 to 0.2%). The yeasts multiply rapidly during the first 10 to 15 hr of the sponge fermentation to reach 40 x 106 cells per g.

This alcoholic fermentation is followed by a bacterial fermentation which results in the production of lactic acid, a further drop in pH, and a growth to about 75 x 106 cells per g. When the cracker sponges are mixed with additional flour, soda is added to raise the pH and the dough is sheeted after 4 hr dough fermentation. The leavening action is largely due to formation of steam during the short baking period in a hot oven.