ADVERTISEMENTS:

In this article we will discuss about the reason for the spoilage of canned foods, explained with the help of suitable diagrams.

If a canned food contains viable micro-organisms capable of growing in the product at ambient temperatures, then it will spoil. Organisms may be present as a result of an inadequate heat process, under processing, or of post process contamination through container leakage. Spoilage by a single spore former is often diagnostic of under processing since rarely would such a failure be so severe that vegetative organisms would survive.

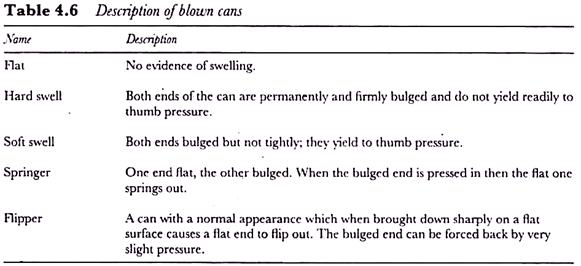

A normal sound can will either be under vacuum with slightly concave ends or have flat ends in those cases where the container is brimful. Spoilage often manifests itself through microbial gas production which causes the ends to distend and a number of different terms are used to describe the extent to which this has occurred (Table 4.6).

The spore-forming anaerobes Clostridium can be either predominantly proteolytic or saccharolytic but both activities are normally accompanied by gas production causing the can to swell. Cans may sometimes swell as a result of chemical action. Defects in the protective lacquer on the inside of the can may allow the contents to attack the metal releasing hydrogen. These hydrogen swells can often be distinguished from microbiological spoilage since the appearance of swelling occurs after long periods of storage and the rate at which the can swells is usually very slow.

In cases where microbial growth occurs without gas production, spoilage will only be apparent once the pack has been opened. Bacillus species, with the exceptions of B. macerans and B. polymyxa, usually break down carbohydrates to produce acid but no gas giving a type of spoilage known as a ‘flat sour’, which describes the characteristics of both the can and the food.

The heat process a product receives is determined largely by its acidity: the more acidic a product is, the milder the heat process applied. Although more complex schemes have been described, the essential classification of canned foods is into low acid (pH > 4.5, or 4.6 in the United States) and acid foods (pH < 4.5 or 4.6).

We have already seen how this is applied to assure safety with the requirement that products with a pH > 4.5 must undergo a botulinum cook to ensure 12 decimal reductions of C. botulinum spores. This is not a concern in acid foods and the F0 applied to products with a pH in the range 4.0-4.5 such as canned tomatoes and sopie canned fruits is generally 0.5-3.0. In higher acidity products such as canned citrus fruits (pH < 3.7) the heat process is equivalent only to a pasteurization.

ADVERTISEMENTS:

A product’s acidity also determines the type of spoilage that may result from under-processing since it can prevent the growth of some spoilage organisms. At normal ambient temperatures (< 38 °C) only mesophilic species will grow. Typical examples would be C. botulinum, C. sporogenes and B. subtilis in low acid products and C. butyricum and C. pasteurianum in products with a pH below 4.5.

Cans are cooled rapidly after processing to prevent spoilage by thermophiles. Thermophilic spores are more likely to survive the normal heat process but would not normally pose a problem. If however a large assemblage of cans is allowed to cool down naturally after retorting, the process will be slow and the cans will spend some time passing through the thermophilic growth range.

Under these conditions surviving thermophilic spores may be able to germinate and grow, spoiling the product before it cools. This may also occur if cans are stored at abnormally high ambient temperatures (>40 °C) and canned foods destined for very hot climates may receive a more stringent process to reduce thermophilic spoilage.

Thermophilic organisms commonly associated with spoilage of low acid canned foods are the saccharolytic organism C. thermosaccharolyticum, B. stearothermophilus and Desulfotomaculumnigrificans. The last of these causes a type of spoilage known as ‘sulfur stinker’. It produces hydrogen sulfide which does not usually distend the can but does give the product an objectionable smell and reacts with iron from the can to cause blackening.

Leakage is the most common cause of microbiological spoilage in canned foods. Cans are the most common containers used for retorted products, although glass jars, rigid plastic containers and soft pouches are also sometimes used. Cans are usually made of two or three parts: the three-part can consists of a base, body and lid while in two part cans the body and base are made from a single piece of metal.

In a three-part can the body seam is electrically welded but the lid on all cans is held in place by a double seam (Figure 4.7). The correct formation and integrity of this seam are crucial to preventing leakage and monitoring seam integrity is an important aspect of quality control procedures in canning.

During processing cans are subjected to extreme stress, particularly when the hot can is cooled down rapidly from processing temperatures. The negative pressure created in the can under these conditions could lead to micro-organisms on the container’s surface or in the cooling water being sucked inside through a small defect in the seam.

During processing cans are subjected to extreme stress, particularly when the hot can is cooled down rapidly from processing temperatures. The negative pressure created in the can under these conditions could lead to micro-organisms on the container’s surface or in the cooling water being sucked inside through a small defect in the seam.

The defect in the hot can that allowed leakage to occur may seal up and be undetectable when the can is cool since leaker spoilage can cause cans to blow. Since the micro-organisms enter the can after processing there is no restriction on the type of organism capable of causing leaker spoilage, therefore the presence of a mixed culture or non-sporing organisms is almost certainly a result of can leakage.

To prevent leaker spoilage it is essential that the outside of cans is clean and uncontaminated and that chlorinated water is used to cool them. Failures in this respect have been the cause of a large typhoid outbreak in Aberdeen, Scotland where cans of corned beef made in the Argentine had been cooled with river water contaminated with Salmonella typhi and in an outbreak of botulism associated with canned salmon where the C. botulinum type E spores which were associated with the raw product contaminated the outside of the cans after processing and were sucked into one can during cooling.

ADVERTISEMENTS:

There have been occasional reports of pre-process spoilage in canned foods where there was an unacceptable delay between preparing the product and heat processing. During this time spoilage may occur although the organisms responsible will have been killed by the heat process.