ADVERTISEMENTS:

In this article we will discuss about the fermentation process of cheese.

Cheese can be defined as a consolidated curd of milk solids in which milk fat is entrapped by coagulated casein. Unlike fermented milks, the physical characteristics of cheese are far removed from those of milk.

This is because protein coagulation proceeds to a greater extent as a result of the use of proteolytic enzymes and much of the water content of the milk separates and is removed in the form of whey. Typically the yield of cheese from milk is of the order of 10%.

ADVERTISEMENTS:

Cheese making can be broken down into a number of relatively simple unit operations. Slight variations of these and the use of different milks combine to generate the huge range of cheeses available today; said to include 78 different types of blue cheese and 36 Camembert’s alone.

Classification of cheeses is made difficult by this diversity and the sometimes rather subtle distinctions between different types. Probably the most successful approach is one based on moisture content, with further subdivision depending on the milk type and the role of micro-organisms in cheese ripening (Table 9.7).

Cheese is a valuable means of conserving many of the nutrients in milk. In many people, it evokes a similar response to wine, playing an indispensible part in the gastronome’s diet and prompting Brillat-Savarin (1755-1826) to coin the rather discomforting aphorism that ‘Dessert without cheese is like a pretty woman with only one eye’.

ADVERTISEMENTS:

Despite this, the attraction of a well-ripened cheese eludes many people and it is sometimes hard to understand how something that can smell distinctly pedal can yield such wonderful flavours. This paradox was encapsulated by a poet, Leon-Paul Fargue, who described Camembert as ‘the feet of God’.

Today cheese making is a major industry worldwide, producing something approaching 10 million tonnes per annum. Much is still practiced on a relatively small scale and accounts for the rich diversity of cheeses still available.

Large-scale industrialized production is increasingly important, however, and is dominated by one variety, Cheddar, which is now produced throughout the world, far removed from the small town in Somerset where it originated.

Cheddar cheese is particularly valued for its smooth texture and good keeping qualities, although products sharing the name can vary dramatically in flavour. In what follows we will describe the basic steps in cheese making with particular reference to the manufacture of Cheddar cheese.

Cow’s milk for cheese production must be free from antibiotics and sanitizing agents that might interfere with the fermentation. Although it is not compulsory, a heat treatment equivalent to pasteurization is usually applied at the start of processing. This helps to ensure a safe product and a reliable fermentation, although cheeses made from raw (unpasteurized) milk have been claimed to possess a better flavour.

The milk is then cooled to the fermentation temperature which, in the case of Cheddar and other English cheeses such as Stilton, Leicester and Wensleydale, is 29-31 °C. The starter organisms used in most cheese making are described as mesophilic starters, strains of Lactococcus lactis and its subspecies.

Thermophilic starters such as Lactobacillus helveticus, Lb. casei, Lb. lactis, Lb. delbrueckii subsp. bulgaricus and Strep, salivarius subsp. thermophilic are used in the production of cheeses like Emmental and Parmesan where a higher incubation temperature is employed.

The role of starter organisms in cheese making is both crucial and complex. Their central function is the fermentation of the milk sugar lactose to lactic acid. This and the resulting decrease in pH contribute to the shelf-life and safety of the cheese and gives a sharp, fresh flavour to the curd.

The stability of the colloidal suspension of casein is also weakened and calcium is released from the casein micelles improving the action of chymosin. After the protein has been coagulated, the acid aids in moisture expulsion and curd shrinkage, processes which govern the final cheese texture.

ADVERTISEMENTS:

There are two different systems for uptake and metabolism of lactose in LAB. In most lactobacilli and Strep, salivarius subsp. thermophilus, lactose is taken up by a specific permease and is then hydrolysed intracellularly by β-galactosidase.

The glucose produced is fermented by the EMP pathway which the galactose also enters after conversion to glucose-6-phosphate by the Leloir pathway (Figure 9.7). Most lactococci and some lactobacilli such as Lb. casei take up lactose by a phosphoenol- pyruvate (PEP)-dependent phosphotransferase system (PTS) which phosphorylates lactose as it is transported into the cell.

The lactose phosphate is then hydrolysed by phospho-β-galactosidase to glucose, which enters the EMP pathway, and galactose- 6-phosphate which is eventually converted to pyruvate via the tagatose-6-phosphate pathway.

These pathways are of practical import in cheese making; in the lactococci, lactose utilization is an unstable, plasmid encoded characteristic and loss of these genes can clearly have serious consequences for milk fermentation.

ADVERTISEMENTS:

Using transduction techniques, molecular biologists have produced strains of Lactococcus lactis in which this property has been stabilized by integration of the lactose utilization genes in the chromosome.

The thermophilic lactobacilli, which employ a lactose permease and β- galactosidase, metabolize the glucose produced preferentially, turning to galactose only when lactose becomes limiting. This can be a problem in some products. The accumulation of galactose can give rise to a brown discolouration during the heat processing of Mozzarella cheese.

In Swiss cheeses such as Emmental, residual galactose can affect product flavour since propionic acid bacteria ferment it in preference to lactate. In doing so they produce a preponderance of acetic (ethanoic) acid which does not confer the usual nutty flavour associated with the equimolar concentrations of acetate and propionate produced by the Propionibacterium from lactate.

ADVERTISEMENTS:

Lactic acid bacteria are nutritionally fastidious and require preformed nucleotides, vitamins, amino acids and peptides to support their growth. To grow to high cell densities and produce acid rapidly in milk, dairy starters must have proteolytic activity to overcome the limitation imposed by the low non-protein nitrogen pool in native milk.

These systems are comprised of proteinases, associated with the surface of the bacterial cell wall, which can hydrolyse casein proteins. Peptidases in the cell wall degrade the oligopeptides produced down to a size that can be transported into the cell (4-5 amino acid residues) where they are further degraded and utilized.

While this ability is essential to starter function, it also plays an important role in the development of cheese flavour during ripening or maturation. Citrate fermentation to diacetyl is required in some cheese varieties and starter cultures for these include species such as Lactococcus lactis subsp. diacetylactis or Leuconostoc cremoris.

Carbon dioxide is another product of this pathway and is important in producing the small eyes in Dutch cheese like Gouda or giving an open texture that will facilitate mould growth in blue-veined cheeses. In other cheese, such as Cheddar, this would be regarded as a textural defect.

ADVERTISEMENTS:

To produce Cheddar cheese, starter culture is added at a level to give 106-107 cfu ml-1. In the past these cultures were grown-up in the dairy from stock cultures or from freeze-dried preparations bought in from commercial suppliers. Nowadays frozen, concentrated cultures that are added directly to the cheese vat are increasingly used because of their ease of handling and the greater security they offer the cheese maker.

This applies particularly to the risk of bacteriophage inhibition of the fermentation which has been a major preoccupation of the cheese maker since it was first identified in New Zealand in the 1930s. Problems of phage infection are not confined to cheese making but have also been encountered in the production of yoghurt and fermented meats.

A bacteriophage is a bacterial virus which in its virulent state infects the bacterial cell, multiplies within it, eventually causing the cell to burst (lysis). When this occurs during a cheese fermentation, acidification slows or even stops causing financial losses to the producer as well as an increased risk that pathogens might grow.

An important source of phage in cheese making is thought to be the starter culture organisms themselves which carry within them lysogenic phages that can be induced into a virulent state. Problems occur particularly when starters contain a single strain or only a few strains and the same culture is re-used over an extended period.

During this time, phages specific to that organism build up in the plant and can be isolated from the whey and from environmental sources such as drains and the atmosphere, increasing the chance of fermentation failure.

In the past, control of this problem has been based on the observation of rigorous hygiene in the dairy, the rotation of starter cultures with differing phage susceptibilities and propagation of starters in phage-inhibitory media which contain phosphate salts to chelate Ca2+ and Mg2+ required for successful phage adsorption to the bacterial cell.

ADVERTISEMENTS:

LAB possess their own resistance mechanisms to phage infection which include restriction/ modification of non-host DNA, inhibition of phage adsorption by alteration or masking of specific receptors on the cell surface, and reduction of burst size (the number of phages released per infected cell).

Most of these mechanisms appear to be plasmid encoded and this has opened the way for new strategies for phage control so that trans-conjugants with enhanced phage resistance are now available.

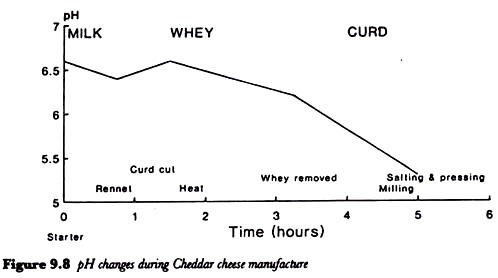

A time course for the production of Cheddar cheese showing pH changes and the timing of different process stages is shown in Figure 9.8. A good starter should produce around 0.2% acidity within an hours incubation. It will multiply up to around 108-109 cfu g-1 in the curd producing an acidity of 0.6-0.7% before its growth is stopped by salting.

After about 45 min rennet is added. The time of renneting and the amount added are other important variables in cheese making which differ with cheese type. Rennet is a preparation from the fourth stomach or abomasum of suckling calves, lambs or goats.

Its most important component is the proteolytic enzyme rennin or chymosin which cleaves k-casein, the protein responsible for the stability of the casein micelle, between phenylalanine 105 and methionine 106.

This releases a 64 amino acid macro-peptide into the whey leaving the hydrophobic para-k-casein attached to the micelle. Loss of the macro-peptide leads to the formation of cross-links between the micelles to form a network entrapping moisture and fat globules.

Authentic chymosin is produced as a slaughterhouse by-product but microbial rennets are available, produced from fungi such as Mucor miehei, Mucor pusillus and Endothia parasitica. These lack the specificity of animal rennet and have been associated with the production of bitter peptides in the cheese.

Now however the genes for chymosin have been cloned into a number of organisms and nature-identical chymosin is available commercially, produced using the bacterium E. coli and yeasts.

After 30-45 min, coagulation of the milk is complete and the process of whey expulsion is started by cutting the curds into approximately 1 cm cubes. Whey expulsion is further assisted by the process known as scalding when the curds, heated to 38-42 °C, shrink and become firmer.

The starter organisms are not inhibited by such temperatures and continue to produce acid which aids curd shrinkage. Cheeses produced using thermophilic starters can be scalded at higher temperatures without arresting acid development. When the acidity has reached the desired level (generally of the order of 0.25%), the whey is run off from the cheese vat.

It is at this stage that the process known as cheddaring occurs. The curd is formed into blocks which are piled up to compress and fuse the curds, expelling more whey. Nowadays the traditional manual process is mechanized in a cheddaring tower.

At the end of cheddaring, the curd has a characteristic fibrous appearance resembling cooked chicken breast. The blocks of curd are then milled into small chips. This facilitates the even distribution of salt which, in Cheddar, is added at a level of between 1.5 and 2% w/w. The salted curd is formed into blocks which are then pressed to expel trapped air and whey.

Finally the cheese is ripened or matured at 10°C to allow flavour development. During this stage, which can last up to five months to produce a mild Cheddar, the microflora is dominated by non-starter lactobacilli and a complex combination of bacterial and enzymic reactions give the cheese its characteristic flavour.

In particular, proteases and peptidases from the starter culture .continue to act, even though the organism can no longer grow. With other proteases from the rennet, they release free amino acids (principally glutamic acid and leucine in Cheddar) and peptides which contribute to the cheese flavour.

In some cases this can give rise to a flavour defect: casein proteins contain a high proportion of hydrophobic amino acid residues such as leucine, proline and phenylalanine and if they are degraded to produce peptides rich in hydrophobic residues, the cheese will have a bitter taste.

The lipolytic and proteolytic activities of moulds play an important role in the maturation of some cheeses. In blue cheeses such as Stilton, Penicillium roquefortii and P. glaucum grow throughout the cheese.

Both can grow at reduced oxygen tensions, but aeration is improved by not pressing the curds and by piercing the blocks of curd with needles. P. camembertii and P. caseicolum are associated with surface-ripened soft cheeses such as Camembert and Brie.

The keeping qualities of cheese vary with the type but are always much superior to those of milk. This is principally the result of the reduced pH (around 5.0 in Cheddar), the low water activity produced by whey removal and the dissolution of salt in the remaining moisture.

Under these conditions yeasts and moulds are the main organisms of concern. The latter are effectively controlled by traditional procedures to exclude air such as waxing or by modern refinements such as vacuum packing.