ADVERTISEMENTS:

Let us make an in-depth study of the fermentation technology. After reading this article you will learn about 1. Meaning of Fermentation Technology 2. Fermentation Methodology 3. Types of Fermentation Processes 4. Procedure of Fermentation and 5. Categories of Fermentation Technology.

Meaning of Fermentation Technology:

Fermentation is the process involving the biochemical activity of organisms, during their growth, development, reproduction, even senescence and death. Fermentation technology is the use of organisms to produce food, pharmaceuticals and alcoholic beverages on a large scale industrial basis.

The basic principle involved in the industrial fermentation technology is that organisms are grown under suitable conditions, by providing raw materials meeting all the necessary requirements such as carbon, nitrogen, salts, trace elements and vitamins.

ADVERTISEMENTS:

The end products formed as a result of their metabolism during their life span are released into the media, which are extracted for use by human being and that have a high commercial value. The major products of fermentation technology produced economically on a large scale industrial basis are wine, beer, cider, vinegar, ethanol, cheese, hormones, antibiotics, complete proteins, enzymes and other useful products.

Fermentation Methodology:

Fermentation process is carried out in a container called the fermentor or bioreactor. The design and nature of the fermentor varies depending upon the type of fermentation carried out. Invariably all the fermentors have facilities to measure some of the fermentation parameters like temperature, pressure, pH, elapsed fermentation time, liquid level, mass etc.

The different types of fermentors are:

(1) External recycle airlift fermentor—for producing bacterial biomass, with methanol as substrate.

ADVERTISEMENTS:

(2) Internal recycle airlift fermentor—for producing yeast with oil as substrate.

(3) Tubular tower fermentor—Used for making beer, wine, vinegar etc.

(4) Nathan fermentor—used in brewing industry.

(5) Stirred fermentor—used for making antibiotics.

Types of Fermentation Processes:

There are three different process of fermentation viz.:

(1) Batch fermentation

(2) Feb-batch fermentation and

(3) Continuous culture.

Batch fermentation:

ADVERTISEMENTS:

This term is attributed to that type of fermentation wherein there is change in culture medium, number of microorganisms and the amount of the product produced (i.e. the metabolite or target protein). In batch fermentation six phases of the microbial growth are seen.

(a) Lag phase:

Immediately after inoculation, there is no increase in the numbers of the microbial cells for some time and this period is called lag phase. This is in order that the organisms adjust to the new environment they are inoculated into.

(b) Acceleration phase:

ADVERTISEMENTS:

The period when the cells just start increasing in numbers is known as acceleration phase.

(c) Log phase:

This is the time period when the cell numbers steadily increase.

(d) Deceleration phase:

ADVERTISEMENTS:

The duration when the steady growth declines.

(e) Stationary phase:

The period where there is no change in the microbial cell number is the stationary phase. This phase is attained due to depletion of carbon source or accumulation of the end products.

(f) Death phase:

ADVERTISEMENTS:

The period in which the cell numbers decrease steadily is the death phase. This is due to death of the cells because of cessation of metabolic activity and depletion of energy resources. Depending upon the product required the different phases of the cell growth are maintained. For microbial mass the log phase is preferred. For production of secondary metabolites i.e. antibiotics, the stationary phase is preferred.

Feb-batch fermentation:

In this type of fermentation, freshly prepared culture media is added at regular intervals without removing the culture fluid. This increases the volume of the fermentation culture. This type of fermentation is used for production of proteins from recombinant microorganisms.

Continuous fermentation:

In this type of fermentation the products are removed continuously along with the cells and the same is replenished with the cell girth and addition of fresh culture media. This results in a steady or constant volume of the contents of the fermentor. This type of fermentation is used for the production of single cell protein (S.S.P), antibiotics and organic solvents.

Procedure of Fermentation:

(a) Depending upon the type of product required, a particular bioreactor is selected.

ADVERTISEMENTS:

(b) A suitable substrate in liquid media is added at a specific temperature, pH and then diluted.

(c) The organism (microbe, animal/plant cell, sub-cellular organelle or enzyme) is added to it.

(d) Then it is incubated at a specific temperature for the specified time.

(e) The incubation may either be aerobic or anaerobic.

i. Aerobic conditions are created by bubbling oxygen through the medium.

ii. Anaerobic conditions are created by using closed vessels, wherein oxygen cannot diffuse into the media and the oxygen present just above is replaced by carbon dioxide released.

ADVERTISEMENTS:

(f) After the specified time interval, the products are removed, as some of the products are toxic to the growing cell or at least inhibitory to their growth. The organisms are re-circulated. The process of removal of the products is called downstream processing.

Example of batch fermentation technology using tubular tower fermentor:

The simplest and the most commonly used fermentation technology is the preparation of curd from milk.

The details of the technology are as under:

The fermentor or bioreactor:

Mud pot or steel cooking vessel or a dish or a cup

The substrate:

Milk

The specific temperature:

37°C

The organism:

Preformed curd (containing the microbe Lactobacillus cecai)

The incubation:

At 37° C for 6-8 hours

The aeration:

The process is anaerobic

The process:

Preformed curd has microbes that utilize lactose present in the milk. Lactose is hydrolysed into glucose and galactose. Galactose is converted to glucose. Glucose is broken down to lactic acid by glycolytic pathway. The lactic acid produced, lowers the pH of milk from 6.6 to 4.5. The isoelectric pH of milk protein-casein is 4.5. At this pH, casein precipitates forming fine micelles in the milk thereby curdling it.

Milk is warmed before adding it to the fermentor so as to maintain the temperature required for the growth of the microbes. The container/fermentor is not disturbed (no stirring is taken up) so that the precipitation is uniform.

The elapsed time i.e. the time required to form the curd is crucial; it depends upon the atmospheric temperature. During summer the curd is formed within 4-6 hours, whereas during rainy season it takes 6-8 hours and in winter it takes almost 8-12 hours. The process is anaerobic hence it is better to keep the vessel closed. Though it cannot be air tight but still the surface of the milk that contains fat prevents air from penetrating in the liquid, furthermore the metabolizing microbes replace the oxygen with carbon dioxide released.

Example of continuous fermentation technology using stirred fermentor:

Another common fermentation technology is the process of food digestion.

The details of the technology are as under:

The fermentor or bioreactor:

Stomach (G.I. tract)

The substrate:

Food

The specific temperature:

37°C

The organism:

Enzymes, microbes, acids etc.

The Incubation:

At 37°C for 3-4 hours

The aeration:

The process is anaerobic

The process:

The food eaten by us is stored in the stomach where HC1 and some enzymes are secreted that convert food into chyme (semi solid). The food stays for 3-4 hours at 37° C. The digested food is absorbed in the blood and the undigested food is excreted. This is a continuous fermentation because the substrate (food) is continuously added and the products (digested/undigested material) are continuously removed. Stomach-the fermentor is a stirred type i.e. the peristaltic movement of the gastro-intestinal tract mixes the food.

Categories of Fermentation Technology:

Fermentation technology can be grouped into four major categories viz.

1. Microbial biomass production:

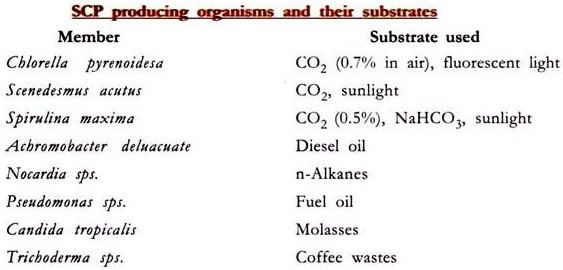

Microbial cells (biomass) are grown commercially as continuous culture on a large scale (1500/m3). The microbial cells including algae, bacteria, yeasts, moulds and mushrooms are dried and used as a good source of a complete protein called ‘single cell protein (SCP)’ which serves as human food or animal feed. The incubation of wheat flour for preparation of ‘tandoori roti’ and rice flour for ‘dosa’ are good examples for the production of single cell protein.

These two food stuffs or the common food are usually lacking or not having sufficient quantities of lysine and methionine amino acids. Single cell protein produced by different sources is a rich source of different essential amino acids, thereby supplementing the amino acid lacking in a particular food. The incubation of the foods results in the growth of the microbial biomass, producing the SCP.

SCP produced by some microorganisms is lysine rich whereas those produced by others are methionine rich. The substrates used by the microbes producing the single cell protein range from carbohydrates to hydrocarbons and petrochemicals. Other organisms use the gases—methane, ethane, propane, n-butane etc as substrate for fermentation.

Lysine-rich SCP (7g lysine/16 g N) producing organisms are Chlorella sorokiniana, Cellulomonas alkaligens, Saccharomyces cerevisiae etc. Methionine-rich SCP (2g methionine/16 g N) producing organisms are Methylococcus capsulatus, Saccharomyces cerevisiae and Aspergillus.

2. Microbial metabolites:

During the metabolism of microbial cells a number of compounds are produced and many are secreted out of the cell, which can be easily extracted and are very useful to man and animals. Therefore fermentation by microbial cells is carried out on an industrial scale, in order to get various metabolites.

The metabolites produced by the microbes can be grouped into two categories:

(a) Primary metabolites and

(b) Secondary metabolites.

(a) Primary metabolites:

Metabolites which are produced by the metabolism required for the maintenance of the minimum life process of a microbe are known as primary metabolites. The primary metabolites are produced in abundance at an early stage of growth. Examples of primary metabolites are ethanol, citric, acid, glutamic acid, lactic acid, acetic acid, acetone, formic acid, butanol, propionic acid, dihydroxy-acetone, glycerol etc. These metabolites are produced by fermentation technology applying different microbes under varying conditions of fermentation.

(b) Secondary metabolites:

Secondary metabolites are those metabolites, which are not produced directly by the metabolism required for the vital life process of microbes, instead are produced by some specialized metabolic process. However most of the secondary metabolites are derived from the primary metabolites. The secondary metabolites include the antibiotics, alkaloids, toxic pigments, vitamins etc.

Antibiotics:

An antibiotic is a substance produced by a microorganism which can inhibit growth or completely destroy other microorganisms. The antibiotics are not synthesized by the microorganism by a single gene, instead a set of 10-20 genes takes part in the synthesis of an antibiotic. The genes for antibiotic are mostly located on the plasmid, however in some microbes they are found on the chromosomal DNA.

About 45000 different antibiotics have been discovered so far, but only about 100 are used for human treatment, because only those antibiotics can be used which are toxic to the invading microbe but non-toxic for the human.

Some of the antibiotics and the microbes which produce them are:

Amphotericin-B—Streptomyces nodosus Chloramphenicol—Streptomyces venezuelae, Erythromycin—S. eythirus, Gentamycin—Micromonospora purpurea, Gramicidin—Bacillus brevis, Penicillin—Penicillin chryosogen Streptomycin—S. grises, Tetracycline—S. aureofacins.

These microbes are grown under suitable fermentation conditions so as to get the desired antibiotic. Mutant microbes are used for industrial production of antibiotics.

3. Microbial enzymes:

When microbes are cultured, they secrete some enzymes into the media and these enzymes are extracted and widely used in several industries like detergent, food processing, brewing and pharmaceutical. They are also used for diagnostic, scientific and analytical purposes. Biotechnological methods are used to engineer microbial cells so as to induce them to produce enzymes like renin by E. coli and amylases by Bacillus stearothermophillis.

These enzymes are generally bound to matrix or in some manner retained in the reactor to be reused and hence these are called immobilized enzymes. In some cases the microorganism producing enzyme is immobilized. Some of the enzymes produced by fermenting microbes are—Glucose oxidase, protease glucoamylase, amylase, glucose isomerase, rennin, pectinase, superoxide dismutase, cellulase, invertase, lactase and lipase.

Some thermophile bacteria produce enzymes that are thermo-stable and which can be used in industrial processes at high temperatures, ex. glyceraldehyde-3-phosphate dehydrogenase, phosphofructo-kinase, alcohol dehydrogenase, superoxide dismutase and restriction endonucleases, which are produced by Bacillus stearothermophillis thermoysia. Further, genes for thermophilic enzymes are introduced into E. coli, which is cultured for producing the thermophilic enzymes.

4. Bioconversion, biotransformation or modification of the substrate:

The fermenting microbes have got the capacity to convert an added substrate into some more valuable product, ex. conversion of ethanol to acetic acid (vinegar), isopropanol to acetone, glucose to gluconic acid, sorbitol to sorbose (this is used in the manufacture of vitamin C), sterols to steroids.

Among all these bioconversions, the production of steroids is the most widely applied fermentation biotechnology for the conversion of sterols into steroids, like cortisone, hydroxycortisone, prednisone, dexamethasone, testosterone, estradiol etc. Hitherto, steroids were produced by chemical methods, which were laborious and costly.

For instance the chemical synthesis of cortisone required 37 steps under extreme conditions. One of the steps is introduction of oxygen at position 11 in the steroid nucleus. The microbe Rhizopus arrhizus being capable of hydroxylating progesterone (a steroid) at position 11 is used in the fermentation to produce progesterone an intermediate in the synthesis of cortisone. Thus, this reduced the chemical synthesis steps from 37 to 11 and all under normal conditions, thereby making it economical and easy. Steroids are used as anti-inflammatory agents, contraceptives, treating hormonal insufficiency, allergy, skin diseases etc.

Downstream processing (DSP):

The method by which the products of fermentation are recovered and separated is known as downstream processing. This forms the major (about 85%) portion of the complete fermentation technology. There are various methods by which DSP is carried out.

First of all, the broth is conditioned i.e. the cells are aggregated and form large clumps, which makes the separation easier. The conditioning is done by heating, freezing, pH change, antigen-antibody reactions etc. Then the conditioned broth is used for the separation of the constituents for which techniques like sedimentation, floatation, filtration, ultra-filtration, centrifugation and micro-filtration are applied.