ADVERTISEMENTS:

Read this article to learn about the methods, effects and applications of immobilization of enzymes and cells.

Traditionally, enzymes in free solutions (i.e. in soluble or free form) react with substrates to result in products. Such use of enzymes is wasteful, particularly for industrial purposes, since enzymes are not stable, and they cannot be recovered for reuse.

Immobilization of enzymes (or cells) refers to the technique of confining/anchoring the enzymes (or cells) in or on an inert support for their stability and functional reuse. By employing this technique, enzymes are made more efficient and cost-effective for their industrial use. Some workers regard immobilization as a goose with a golden egg in enzyme technology. Immobilized enzymes retain their structural conformation necessary for catalysis.

ADVERTISEMENTS:

There are several advantages of immobilized enzymes:

a. Stable and more efficient in function.

b. Can be reused again and again.

c. Products are enzyme-free.

ADVERTISEMENTS:

d. Ideal for multi-enzyme reaction systems.

e. Control of enzyme function is easy.

f. Suitable for industrial and medical use.

g. Minimize effluent disposal problems.

There are however, certain disadvantages also associated with immobilization.

a. The possibility of loss of biological activity of an enzyme during immobilization or while it is in use.

b. Immobilization is an expensive affair often requiring sophisticated equipment.

Immobilized enzymes are generally preferred over immobilized cells due to specificity to yield the products in pure form. However, there are several advantages of using immobilized multi-enzyme systems such as organelles and whole cells over immobilized enzymes. The immobilized cells possess the natural environment with cofactor availability (and also its regeneration capability) and are particularly suitable for multiple enzymatic reactions.

Methods of Immobilization:

The commonly employed techniques for immobilization of enzymes are—adsorption, entrapment, covalent binding and cross-linking.

Adsorption:

ADVERTISEMENTS:

Adsorption involves the physical binding of enzymes (or cells) on the surface of an inert support. The support materials may be inorganic (e.g. alumina, silica gel, calcium phosphate gel, glass) or organic (starch, carboxymethyl cellulose, DEAE-cellulose, DEAE-sephadex).

Adsorption of enzyme molecules (on the inert support) involves weak forces such as van der Waals forces and hydrogen bonds (Fig. 21.3). Therefore, the adsorbed enzymes can be easily removed by minor changes in pH, ionic strength or temperature. This is a disadvantage for industrial use of enzymes.

Entrapment:

Enzymes can be immobilized by physical entrapment inside a polymer or a gel matrix. The size of the matrix pores is such that the enzyme is retained while the substrate and product molecules pass through. In this technique, commonly referred to as lattice entrapment, the enzyme (or cell) is not subjected to strong binding forces and structural distortions.

ADVERTISEMENTS:

Some deactivation may however, occur during immobilization process due to changes in pH or temperature or addition of solvents. The matrices used for entrapping of enzymes include polyacrylamide gel, collagen, gelatin, starch, cellulose, silicone and rubber. Enzymes can be entrapped by several ways.

1. Enzyme inclusion in gels:

This is an entrapment of enzymes inside the gels (Fig. 21.4A).

ADVERTISEMENTS:

2. Enzyme inclusion in fibres:

The enzymes are trapped in a fibre format of the matrix (Fig. 21.4B).

ADVERTISEMENTS:

3. Enzyme inclusion in microcapsules:

In this case, the enzymes are trapped inside a microcapsule matrix (Fig. 21.4C). The hydrophobic and hydrophilic forms of the matrix polymerise to form a microcapsule containing enzyme molecules inside. The major limitation for entrapment of enzymes is their leakage from the matrix. Most workers prefer to use the technique of entrapment for immobilization of whole cells. Entrapped cells are in use for industrial production of amino acids (L-isoleucine, L-aspartic acid), L-malic acid and hydroquinone.

Microencapsulation:

Microencapsulation is a type of entrapment. It refers to the process of spherical particle formation wherein a liquid or suspension is enclosed in a semipermeable membrane. The membrane may be polymeric, lipoidal, lipoprotein-based or non-ionic in nature. There are three distinct ways of microencapsulation.

1. Building of special membrane reactors.

2. Formation of emulsions.

3. Stabilization of emulsions to form microcapsules.

ADVERTISEMENTS:

Microencapsulation is recently being used for immobilization of enzymes and mammalian cells. For instance, pancreatic cells grown in cultures can be immobilized by microencapsulation. Hybridoma cells have also been immobilized successfully by this technique.

Covalent Binding:

Immobilization of the enzymes can be achieved by creation of covalent bonds between the chemical groups of enzymes and the chemical groups of the support (Fig. 21.5). This technique is widely used. However, covalent binding is often associated with loss of some enzyme activity. The inert support usually requires pretreatment (to form pre-activated support) before it binds to enzyme. The following are the common methods of covalent binding.

1. Cyanogen bromide activation:

ADVERTISEMENTS:

The inert support materials (cellulose, sepharose, sephadex) containing glycol groups are activated by CNBr, which then bind to enzymes and immobilize them (Fig. 21.6A).

2. Diazotation:

Some of the support materials (amino benzyl cellulose, amino derivatives of polystyrene, aminosilanized porous glass) are subjected to diazotation on treatment with NaNO2 and HCI. They, in turn, bind covalently to tyrosyl or histidyl groups of enzymes (Fig. 21.6B).

3. Peptide bond formation:

Enzyme immobilization can also be achieved by the formation of peptide bonds between the amino (or carboxyl) groups of the support and the carboxyl (or amino) groups of enzymes (Fig. 21.6C). The support material is first chemically treated to form active functional groups.

4. Activation by bi- or poly-functional reagents:

Some of the reagents such as glutaraldehyde can be used to create bonds between amino groups of enzymes and amino groups of support (e.g. aminoethylcellulose, albumin, amino alkylated porous glass). This is depicted in Fig. 21.6D.

Cross-Linking:

The absence of a solid support is a characteristic feature of immobilization of enzymes by cross- linking. The enzyme molecules are immobilized by creating cross-links between them, through the involvement of poly-functional reagents. These reagents in fact react with the enzyme molecules and create bridges which form the backbone to hold enzyme molecules (Fig. 21.7). There are several reagents in use for cross-linking. These include glutaraldehyde, diazobenzidine, hexamethylene diisocyanate and toluene di- isothiocyanate.

Glutaraldehyde is the most extensively used cross-linking reagent. It reacts with lysyl residues of the enzymes and forms a Schiff’s base. The cross links formed between the enzyme and glutaraldehyde are irreversible and can withstand extreme pH and temperature. Glutaraldehyde cross- linking has been successfully used to immobilize several industrial enzymes e.g. glucose isomerase, penicillin amidase. The technique of cross-linking is quite simple and cost-effective. But the disadvantage is that it involves the risk of denaturation of the enzyme by the poly-functional reagent.

Choice of Immobilization Technique:

The selection of a particular method for immobilization of enzymes is based on a trial and error approach to choose the ideal one. Among the factors that decide a technique, the enzyme catalytic activity, stability, regenerability and cost factor are important.

Immobilization of L-amino acid acylase:

L-Amino acid acylase was the first enzyme to be immobilized by a group of Japanese workers (Chibata and Tosa, 1969). More than 40 different immobilization methods were attempted by this group. Only three of them were found be useful. They were covalent binding to iodoacetyl cellulose, ionic binding to DEAE-Sephadex and entrapment within polyacrylamide.

Stabilization of Soluble Enzymes:

Some of the enzymes cannot be immobilized and they have to be used in soluble form e.g. enzymes used in liquid detergents, some diagnostic reagents and food additives. Such enzymes can be stabilized by using certain additives or by chemical modifications. The stabilized enzymes have longer half-lives, although they cannot be recycled. Some important methods of enzyme stabilization are briefly described.

Solvent Stabilization:

Certain solvents at low concentrations stabilize the enzymes, while at high concentrations the enzymes get denatured e.g. acetone (5%) and ethanol (5%) can stabilize benzyl alcohol dehydrogenase.

Substrate Stabilization:

The active site of an enzyme can be stabilized by adding substrates e.g. starch stabilizes a-amylase; glucose stabilizes glucose isomerase.

Stabilization by Polymers:

Enzymes can be stabilized, particularly against increased temperature, by addition of polymers such as gelatin, albumin and polyethylene glycol.

Stabilization by Salts:

Stability of metalloenzymes can be achieved by adding salts such as Ca, Fe, Mn, Cu and Zn e.g. proteases can be stabilized by adding calcium.

Stabilization by Chemical Modifications:

Enzymes can be stabilized by suitable chemical modifications without loss of biological activity. There are several types of chemical modifications.

a. Addition of poly-amino side chains e.g. polytyrosine, polyglycine.

b. Acylation of enzymes by adding groups such as acetyl, propionyl and succinyl.

Stabilization by Rebuilding:

Theoretically, the stability of the enzymes is due to hydrophobic interactions in the core of the enzyme. It is therefore, proposed that enzymes can be stabilized by enhancing hydrophobic interactions. For this purpose, the enzyme is first unfold and then rebuilt in one of the following ways (Fig. 21.8).

1. The enzyme can be chemically treated (e.g. urea and a disulfide) and then refolded.

2. The refolding can be done in the presence of low molecular weight ligands.

3. For certain enzymes, refolding at higher temperatures (around 50°C) stabilize them.

Stabilization by Site-Directed Mutagenesis:

Site-directed mutagenesis has been successfully used to produce more stable and functionally more efficient enzymes e.g. subtilisin E.

Immobilization of Cells:

Immobilized individual enzymes can be successfully used for single-step reactions. They are, however, not suitable for multi-enzyme reactions and for the reactions requiring cofactors. The whole cells or cellular organelles can be immobilized to serve as multi-enzyme systems. In addition, immobilized cells rather than enzymes are sometimes preferred even for single reactions, due to cost factor in isolating enzymes. For the enzymes which depend on the special arrangement of the membrane, cell immobilization is preferred.

Immobilized cells have been traditionally used for the treatment of sewage. The techniques employed for immobilization of cells are almost the same as that used for immobilization of enzymes with appropriate modifications. Entrapment and surface attachment techniques are commonly used. Gels, and to some extent membranes, are also employed.

Immobilized Viable Cells:

The viability of the cells can be preserved by mild immobilization. Such immobilized cells are particularly useful for fermentations. Sometimes mammalian cell cultures are made to function as immobilized viable cells.

Immobilized Non-viable Cells:

In many instances, immobilized non-viable cells are preferred over the enzymes or even the viable cells. This is mainly because of the costly isolation and purification processes. The best example is the immobilization of cells containing glucose isomerase for the industrial production of high fructose syrup. Other important examples of microbial biocatalysts and their applications are given in Table 21.5.

Limitations of Immobilizing Eukaryotic Cells:

Prokaryotic cells (particularly bacterial) are mainly used for immobilization. It is also possible to immobilize eukaryotic plant and animal cells. Due to the presence of cellular organelles, the metabolism of eukaryotic cells is slow. Thus, for the industrial production of biochemical, prokaryotic cells are preferred. However, for the production of complex proteins (e.g. immunoglobulin’s) and for the proteins that undergo post- translational modifications, eukaryotic cells may be used.

Effect of Immobilization on Enzyme Properties:

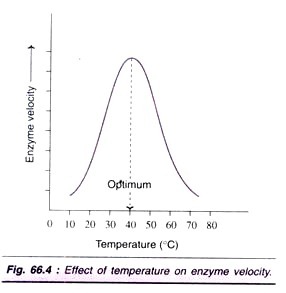

Enzyme immobilization is frequently associated with alterations in enzyme properties, particularly the kinetic properties of enzymes.

Some of them are listed below:

1. There is a substantial decrease in the enzyme specificity. This may be due to conformational changes that occur when the enzyme gets immobilized.

2. The kinetic constants Km and Vmax of an immobilized enzyme differ from that of the native enzyme. This is because the conformational change of the enzyme will affect the affinity between enzyme and substrate.

Immobilized Enzyme Reactors:

The immobilized enzymes cells are utilized in the industrial processes in the form of enzyme reactors. They are broadly of two types — batch reactors and continuous reactors. The frequently used enzyme reactors are shown in Fig. 21.9.

Batch Reactors:

In batch reactors, the immobilized enzymes and substrates are placed, and the reaction is allowed to take place under constant stirring. As the reaction is completed, the product is separated from the enzyme (usually by denaturation).

Soluble enzymes are commonly used in batch reactors. It is rather difficult to separate the soluble enzymes from the products; hence there is a limitation of their reuse. However, special techniques have been developed for recovery of soluble enzymes, although this may result in loss of enzyme activity.

Stirred tank reactors:

The simplest form of batch reactor is the stirred tank reactor (Fig. 21.9A). It is composed of a reactor fitted with a stirrer that allows good mixing, and appropriate temperature and pH control. However, there may occur loss of some enzyme activity. A modification of stirred tank reactor is basket reactor. In this system, the enzyme is retained over the impeller blades. Both stirred tank reactor and basket reactor have a well-mixed flow pattern.

Plug flow type reactors:

These reactors are alternatives to flow pattern type of reactors. The flow rate of fluids controlled by a plug system. The plug flow type reactors may be in the form of packed bed or fluidized bed (Fig. 21.9B and 21.9C). These reactors are particularly useful when there occurs inadequate product formation in flow type reactors. Further, plug flow reactors are also useful for obtaining kinetic data on the reaction systems.

Continuous Reactors:

In continuous enzyme reactors, the substrate is added continuously while the product is removed simultaneously. Immobilized enzymes can also be used for continuous operation. Continuous reactors have certain advantages over batch reactors. These include control over the product formation, convenient operation of the system and easy automation of the entire process. There are mainly two types of continuous reactors-continuous stirred tank reactor (CSTR) and plug reactor (PR). A diagrammatic representation of CSTR is depicted in Fig. 21.9D. CSTR is ideal for good product formation.

Membrane Reactors:

Several membranes with a variety of chemical compositions can be used. The commonly used membrane materials include polysulfone, polyamide and cellulose acetate. The biocatalysts (enzymes or cells) are normally retained on the membranes of the reactor. The substrate is introduced into reactor while the product passes out. Good mixing in the reactor can be achieved by using stirrer (Fig. 21.10A). In a continuous membrane reactor, the biocatalysts are held over membrane layers on to which substrate molecules are passed (Fig. 21.10B).

In a recycle model membrane reactor, the contents (i.e. the solution containing enzymes, cofactors, and substrates along with freshly released product are recycled by using a pump (Fig. 21.10C). The product passes out which can be recovered.

Applications of Immobilized Enzymes and Cells:

Immobilized enzymes and cells are very widely used for industrial, analytical and therapeutic purpose, besides their involvement in food production and exploring the knowledge of biochemistry, microbiology and other allied specialties. A brief account of the industrial applications of immobilized cells is given in Table 21.5.

Manufacture of Commercial Products:

A selected list of important immobilized enzymes and their industrial applications is given in Table 21.6. Some details on the manufacture of L-amino acids and high fructose syrup are given hereunder.

Production of L-Amino Acids:

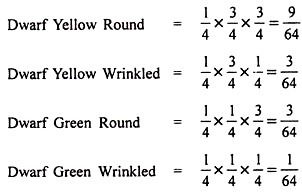

L-Amino acids (and not D-amino acids) are very important for use in food and feed supplements and medical purposes. The chemical methods employed for their production result in a racemic mixture of D- and L-amino acids. They can be acylated to form D, L-acyl amino acids. The immobilized enzyme aminoacylase (frequently immobilized on DEAE sephadex) can selectively hydrolyse D, L-acyl amino acids to produce L-amino acids.

The free L-amino acids can separated from the un-hydrolysed D-acyl amino acids. The latter can be recemized to D, L-acyl amino acids and recycled through the enzyme reactor containing immobilized aminoacylase. Huge quantities of L-methionine, L-phenylalanine L-tryptophan and L-valine are produced worldwide by this approach.

Production of High Fructose Syrup:

Fructose is the sweetest among the monosaccharide’s, and has twice the sweetening strength of sucrose. Glucose is about 75% as sweet as sucrose. Therefore, glucose (the most abundant monosaccharide) cannot be a good substitute for sucrose for sweetening. Thus, there is a great demand for fructose which is very sweet, but has the same calorific value as that of glucose or sucrose.

High fructose syrup (HFS) contains approximately equivalent amounts of glucose and fructose. HFS is almost similar to sucrose from nutritional point of view. HFS is a good substitute for sugar in the preparation of soft drinks, processed foods and baking.

High fructose syrup can be produced from glucose by employing an immobilized enzyme glucose isomerase. The starch containing raw materials (wheat, potato, corn) are subjected to hydrolysis to produce glucose. Glucose isomerase then isomerizes glucose to fructose (Fig. 21.11). The product formed is HFS containing about 50% fructose. (Note: Some authors use the term high fructose corn syrup i.e. HFCS in place of HFS).

Glucose isomerase:

This is an intracellular enzyme produced by a number of microorganisms. The species of Arthrobacter, Bacillus and Streptomyces are the preferred sources. Being an intracellular enzyme, the isolation of glucose isomerase without loss of biological activity requires special and costly techniques. Many a times, whole cells or partly broken cells are immobilized and used.

Immobilized Enzymes and Cells- Analytical Applications:

In Biochemical Analysis:

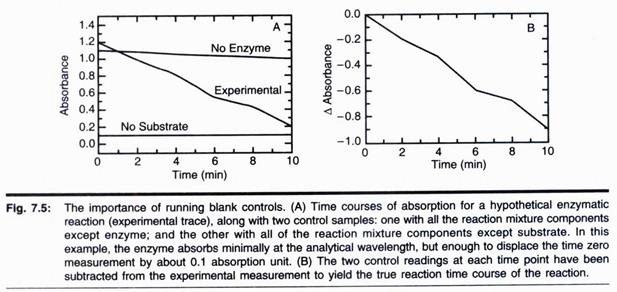

Immobilized enzymes (or cells) can be used for the development of precise and specific analytical techniques for the estimation of several biochemical compounds. The principle of analytical assay primarily involves the action of the immobilized enzyme on the substrate.

A decrease in the substrate concentration or an increase in the product level or an alteration in the cofactor concentration can be used for the assay. A selected list of examples of immobilized enzymes used in the assay of some substances is given in Table 21.7. Two types of detector systems are commonly employed.

Thermistors are heat measuring devices which can record the heat generated in an enzyme catalysed reaction. Electrode devices are used for measuring potential differences in the reaction system. In the Fig. 21.12, an enzyme thermistor and an enzyme electrode, along with a specific urease electrode are depicted.

In Affinity Chromatography and Purification:

Immobilized enzymes can be used in affinity chromatography. Based on the property of affinity, it is possible to purify several compounds e.g. antigens, antibodies, cofactors.