ADVERTISEMENTS:

Design of medium is carried out on the basis of the objective set for.

Growth and Production Medium:

All growth processes are endergonic. In the course of cellular growth, organic and inorganic molecules like glucose, NH3, water and CO2 may be synthesized to form biomass product.

ADVERTISEMENTS:

Supply of energy is needed for growth. It must come from chemical energy of oxidation of medium nutrients or from light energy.

In medium design procedure the first and foremost importance is to provide suitable and sufficient nutrients (reactants) and in appropriate proportions for a specified amount of biomass (products) to be synthesized.

The most suitable energy and/or carbonaceous nutrient source are selected on the basis of experimental results performed with different energy/carbon source. Present day industrial bioprocessing uses starch or molasses as the commonest carbon or energy source. For computing the necessary amounts of various substrates reaction stoichiometry is useful.

It requires the knowledge of the elemental composition of the product biomass (e.g. microorganism). Besides biomass, if fermentative production of other materials occur, the chemical compositions of the major products are also required in ascertaining nutrient medium composition.

ADVERTISEMENTS:

Design of nutrient medium composition is not only important in microbial cell culture system but also the nutrient regime is an important factor in mammalian and plant cell culture bio-processing. Its regime may affect both growth and product synthesis.

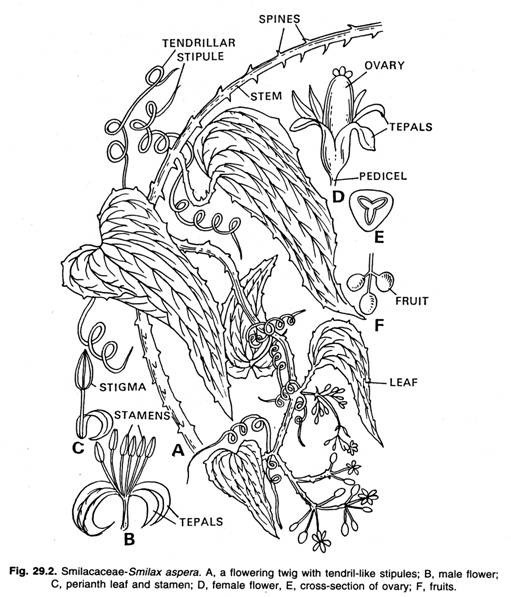

For cultivations of plant cells most of the used medium has a defined design of chemical composition. The media design for the growth of plant tissue/cells is more complex and costly. This is due to the inclusion of plant growth regulators in the media. Optimization in media design in case of plant cell culture mostly confines to carbon and mineral nutrients.

However, media supporting good biomass growth do not necessarily provide maximal yields of natural products. It necessitated defining ‘maintenance media’ and ‘production media’. Maintenance media supports enhanced cell yield and cell division with reduced product yield. Production media on the other hand gives enhanced product yield at the expense of growth.

So in the medium engineering stoichiometric design based and experimental requirement based media formulation approaches have been used in bioprocessing.

Stoichiometric Design Approach: Material and Energy Balances:

This approach is entirely based on laws of conservation of mass of each element taking part in the bio-reaction. It is essential to balance the elemental requirements for growth and product formation. For example, in hetero-fermentative anaerobic bio-reaction for production of propionic acid by Propionibacter acidipropionici ATCC 25562 (at 30°C, pH 6.8 for 34 hrs.) the minimum carbon requirement in the medium may be determined stoichiometrically.

In this bioprocessing the carbon content of substrate (glucose) was found to be distributed mainly in products propionic acid, acetic acid, CO2 and cell mass. On elemental analysis the carbon content in the cell mass was found to be 44%. The stoichiometric carbon balance in this bioprocessing at the end of fermentation (34 hrs.) period was as below. Propionic acid is rarely formed as a sole product in an acidogenic bioprocessing. It is usually accompanied by formation of acetic acid. This occurs for stoichiometric reasons and to maintain hydrogen and redox balance.

About 95% of the initial substrate carbon present could be accounted in various products. Trace amounts of succinic and isovaleric acids as reported by some workers requiring very sensitive methods of estimation could probably account for the rest of the 5% carbon.

ADVERTISEMENTS:

In anoxic bioprocessing every oxidation is accompanied by a reduction that yield product(s) formed from the substrate. Thus the balance between the oxidized and reduced product provides an important criterion for evaluation of the accuracy of the analysis. An oxidation-reduction (O/R) balance in propionic acid production by the above stated microorganism revealed the values as shown in Table 3.1 and 3.2.

The balance of hydrogen and oxygen were obtained by comparing their ratio in the substrate and product. When in a substrate 2H = 0, its oxidation value is zero. Every additional pair of hydrogen atom constitutes O/R number of -1 and every additional oxygen atom constitutes O/R number of +1. From Table 3.2 O/R index of 0.94 is observed.

ADVERTISEMENTS:

An O/R index close to 1 indicated that all products were accounted for in the right proportions. The deviation from unity accounted for experimental error. Cell composition and product composition data availability can enable one to assess the elemental requirements in medium design considering requirements and constraints. (Table 3.3).

Thus mass and energy balances associated with growing cultures play a great role in media design. The heat of reaction per election transferred to oxygen for a wide variety of organic molecules, the number of available electrons per carbon atom in biomass and the weight fraction of carbon in biomass have been found to be relatively constant.