ADVERTISEMENTS:

1. Chemical Method:

The chemical method is known as the sulfite oxidation method.

It involves the determination of the maximum rate of oxidation of sodium sulfite to sodium sulfate in the presence of c0so4 or CuSO4 catalyst, in which there is no back pressure of dissolved oxygen.

The reaction is independent of sulfite concentration in the range of 0.8 M to 0.02 M. usually, 0.5-0.8 M sodium sulfite solution at pH 7.5-7.8 is used in KLa determination. The course of oxidation is followed by analyzing the unreacted sulfite concentration, using the excess of standard iodine, and back- titrating the unreacted iodine with sodium thiosulfate solution.

ADVERTISEMENTS:

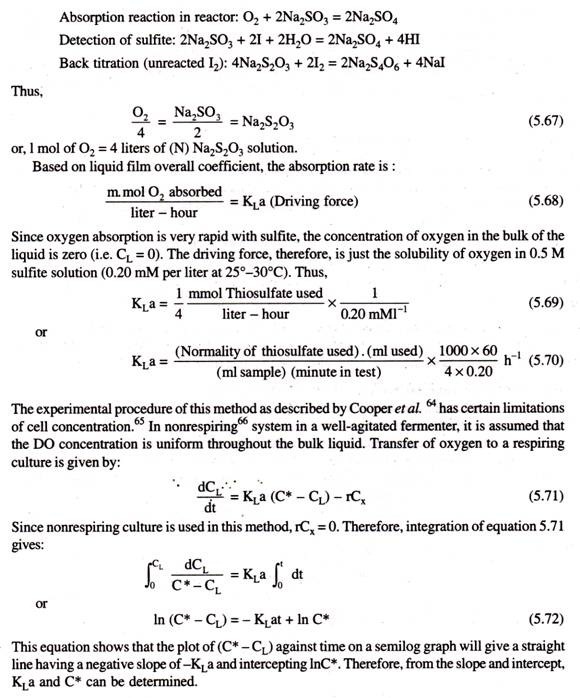

The reactions involved are:

2. Dynamic Differential Gassing-Out (DDGO) Method:

This method, developed by Bandyopadhyay et al., is based on following the DO trace during a brief interruption of aeration in the fermentation system. Only a fast-response, sterilizable DO probe is needed to obtain the necessary data.

The experimental procedure involves degassing (air turn-off) of an actively respiring fermentation mash to record the decrease in DO concentration due to respiration and to obtain the rate of oxygen uptake by the total cell mass. Before critical DO concentration of the organism is reached, aeration is resumed and the increase in DO concentration is recorded as a function of time. The rate of change of DO concentration is measured from this trace. When air is turned off,

3. Dynamic Integral Gassing-Out (DIGO) Method:

The differential gassing-out method has been widely used, but it may incorporate several weak points.For improving some of these weak points, Fujio et al. developed a dynamic integral gassing-out technique based on the differential gassing-out method. Basically, the experimental procedure is the same as that in the previous method.

However, in the case of low DO concentration in equilibrium in microbial cultivation, if one takes the integral form of equation. 5.71, more accurate values will be provided for rCx and dCL/dt, and hence for KLa. The value of rCx in equation 5.71 may be regarded as having a constant value during a short period of time. By rearranging the equation, one can write

(tt -1) gives a straight line, the slope of which directly predicts KLa. The numerical value of B’ will be equal to the equilibrium concentration of DO in the broth under aerated cultivation. Values of rCx and B’ can be obtained from DO trace by performing the experiment as in the method of Bandyopadhyay et al.

4. Oxygen Balance (OB) Method:

Some investigators are of the opinion that oxygen balance over the whole system is the best method for evaluation of KLa in fermenters, because no assumption need be made on the effects of cell, surface active agents, viscosity, and forth. Based on the oxygen balance concept, Mukhopadhyay and Ghose developed a linear mathematical correlation between DO concentration and the proportion of oxygen in inlet and exit air of laboratory fermenter from which KLa can be determined very easily and rapidly, as described below.

When air is blown to a fermentation mash, a fraction of oxygen present in incoming air is dissolved in the liquid, from which the microorganisms absorb oxygen for their respiration and metabolic activities and unabsorbed oxygen goes out with the exit gas. Assuming that during fermentation air density in inlet and exit air does not change appreciably, the incoming air flow rate is equal to the outgoing flow rate (i.e., the pressure drop in the vessel is very low and evaporation loss of the medium is negligible), one can make an oxygen balance in the aerobic bioprocessing system at any time and can write:

5. Enzymic Method (GGO):

Based on the Heineken theory, Linek and his associates ‘ developed a dynamic method to determine KLa in a fermenter using the glucose-glucose oxidase (GGO) system. Assuming absorption of oxygen in the liquid phase as the first-order reaction as well as perfect mixing conditions, the rate of oxygen absorption in the GGO system in a mechanically agitated dispersion (MAD) of gas is given by:

The values of B2 and k can be obtained from the plot of (1 – r’) against Kt values, with B2 as the parameter. The value of Z is obtained from the enzyme probe readings by placing the probe in the gas stream from fermenter and in the GGO system under steady state. For illustration, the plot of the actual concentration in the GGO system and the oxygen probe reading is given in the literature.

6. Merits and Demerits of the Methods:

ADVERTISEMENTS:

i. Limitations of the chemical method:

The chemical method suffers from serious limitations which restrict its use in determining KLa in many chemical and microbial systems. The primary limitation is that aqueous sulfite solution does not adequately simulate fermentation mashes in many properties, which can strongly affect the mass transfer coefficient e.g. viscosity, the presence of surface active agents, the solute concentration, and the presence of microbial cells. It is common for highly viscous mycelial fermentations to exhibit KLa substantially lower than predicted by this method.

Investigations in sparged systems with/without mechanical agitation as well as in a stirred transfer cell without sparging indicate that physical absorption is the rate-controlling process in copper-catalyzed systems if KL is greater than 3 x 10-4m S-1. This can be used to determine the types of equipment and the conditions for which the method can give valid assessments of mass transfer characteristics applicable to fermentation processes and other systems in which the rate of absorption is physically controlled.

It has also been possible to compare coefficients determined in this way with those determined in cultures of E. coli growing in an unstirred, sparged column. These results indicate that KLa increases with expansion of cell concentration, probably because of the effects of the suspended solids on the hydrodynamic conditions near the gas/liquid interface.

ADVERTISEMENTS:

This method has also been applied to determine interfacial areas, and this application depends on the rate being reaction controlled. Between the two extremes of diffusion and reaction control regimes, there is a transition zone in which the sulfite method cannot be applied for either purpose. The results of this method frequently are reported to depend on the choice of catalyst.

The demerit of this method for application in bio-system also relates to difficulties in its use for colored bio-media.

ii. DDGO method:

The merits of the DDGO method are the following:

ADVERTISEMENTS:

(1) It avoids the restrictions of non-respiring mash;

(2) it measures KLa in the actual fermentation system so that the number of assumptions required are less;

(3) results of this method are internally consistent, since only a single measuring device (i.e., DO probe) is used; and

ADVERTISEMENTS:

(4) the method is very simple.

However, many disadvantages of the method have been pointed out, including:

ADVERTISEMENTS:

(1) its applicability to viscous mycelial fermentations is questionable;

(2) it assumes a rapid disengagement of air bubbles from the mash upon termination of aeration (which is not usually the case with highly viscous non-Newtonian mashes);

(3) for some systems (non-Newtonian), it gives appreciably low oxygen uptake values;

(4) in the case of low DO concentration in equilibrium in microbial cultivation, this method gives inaccurate values of rCx and dCL/dt;

(5) the time derivative of DO concentration must be calculated from the DO trace (which might incorporate error during calculations),

(6) at higher broth respiration, accurate measurement itself is difficult; and

ADVERTISEMENTS:

(7) for genetically redesigned cell cultivation, transient degassing may be detrimental.

iii. DIGO method:

This method also has its limitations, due to the fact that it also interrupts the process for a while. For highly responsive bio-systems like genetically engineered or redesigned bio-cell processing, this may be undesirable.

iv. OB method:

As this method does not interrupt the bioprocessing in any manner, traces of DO concentration and percent of oxygen in inlet air and exit gas need to be determined only up to the end of the logarithmic phase of growth. The calculation does not have the scope to incorporate errors, it is easy, and the value is more realistic. It also gives a better result for the recombinant cell bio-system.

v. GGO method:

This method does not need any knowledge of oxygen solubility data in the bioprocessing liquid during estimation. However, calculation is prone to incorporate errors. This method suffers from the fact that it considers a non-respiring system which cannot be simulated with actual fermentation. The requirement that there be no respiration demand during KLa determination mandates that either non-inoculated mash be used, or that respiration be terminated at a particular time by either pasteurization or a respiratory poison. Thus, KLa is measured under artificial conditions.