ADVERTISEMENTS:

In oxygen absorption process the presence of microbial cells in the liquid enhances the rate of oxygen absorption.

Dissolved oxygen in the liquid is picked up by microbial cells and consumed in metabolic processes.

However, many other possible pathways of oxygen transfer in fermentation systems have been described (Tsao & Kemp, 1960, Bennet and Kempe, 1967, Muchmore, 1971; Tsao, 1970).

ADVERTISEMENTS:

Some of them have depicted the possibility of direct oxygen uptake from gas phase to the microbial cell, (Muchmore, 1971). Tsao (1970, 1972) has established that in oxygen absorption process the presence of microbial cells in the liquid enhances the rate of oxygen absorption.

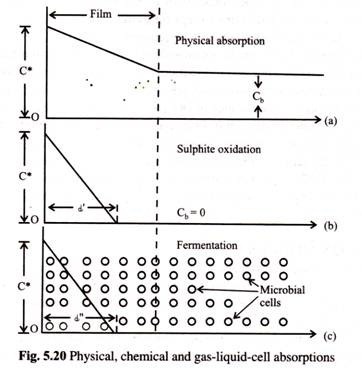

This enhancement mechanism by de-marketing physical, chemical and gas-liquid-cell absorption has been illustrated in Figs. 5.19 and 5.20. It can be visualized a situation with cells totally or partially submerged in the liquid film. Foam fractionation technique of bacterial cell concentration proves that cells, infact have a tendency to crowd themselves into the liquid film due to surface absorption. In other words, cell concentration at the bubble surface is usually higher than that in the bulk liquid.

Since cells consume oxygen molecules being absorbed right at the gas-liquid interface it is believable that cells will effect and enhance the oxygen absorption rate. Illustration of this idea is depicted in Fig. 5.19. This enhancement factor was quantified to be

where M = Dk1/KL02 . k1 being first order rate constant, R° is the rate per unit interface in physical absorption and r is the rate of gas-liquid interface mass transfer per unit interface. Yagi and Yoshida (1975) has also tried to analyze the character of enhancement-factor for oxygen absorption into fermentation broth using Candida tropical is in STF. Defining time average mass flux without viable cells as

In equation (5.42) R is a dimensionless oxygen uptake rate (r1Ck. 12 /DL. Ci), which is proportional to the respiration rate r1, and/or the cell concentration Cx for a given value of 1, x, TӨ, C and / designates dimensionless liquid depth from gas-liquid interface (x/1), dimensionless time (DL/l2), the dimensionless DO concentration (C/C1) for x > O and T = O (initial conditions) and liquid depth corresponding to half the distance between adjacent bubbles respectively. X and t being liquid depth from gas-liquid interface (cm) and time (sees).

Assuming three models as shown in Fig. 5.19 to 5.21 theoretical analysis indicated that in the usual case E has a value negligibly larger than unity, even when accumulation of microorganisms at or near the gas-liquid interface is assumed. Results of experiments with C. tropicalis also confirmed the theoretical prediction and thus it was concluded that except for extreme cases, the effect of respiration of microorganisms on KLa values can practically be ignored.

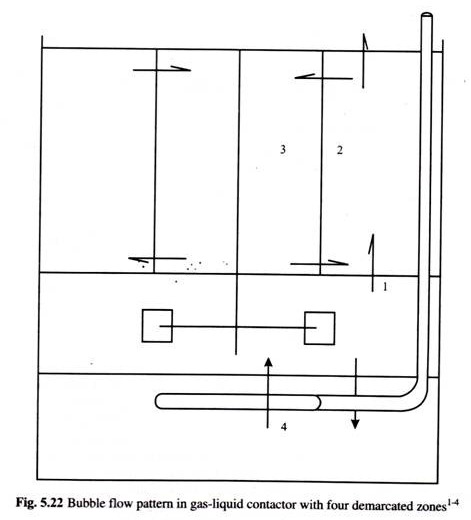

The above mechanisms, however, do not provide any information on the effect of air bubbles distribution and bubble coalescence and redistribution on the oxygen absorption rates in aerated mixing vessels. An integrated mechanism of oxygen absorption in fermentation systems considering distribution of air bubble sizes, concentration of DO, partial pressure of oxygen in bubbles, residence time of bubbles, the volumetric oxygen transfer coefficient, the interaction of liquid flow and moving bubbles and the rate of bubble coalescence and re-dispersion has been forwarded by Taguchi et al. (1972).

The above mechanisms, however, do not provide any information on the effect of air bubbles distribution and bubble coalescence and redistribution on the oxygen absorption rates in aerated mixing vessels. An integrated mechanism of oxygen absorption in fermentation systems considering distribution of air bubble sizes, concentration of DO, partial pressure of oxygen in bubbles, residence time of bubbles, the volumetric oxygen transfer coefficient, the interaction of liquid flow and moving bubbles and the rate of bubble coalescence and re-dispersion has been forwarded by Taguchi et al. (1972).

Dynamic characteristics of bubble flow and mixing has been demarcated into four zones (Fig. 5.22) each with properties as described in Table 5.2. Although it is a complicated mechanism but its expertise appliance in practical system will lead to its better understanding and control.