ADVERTISEMENTS:

Bio-cell Systemic Estimation:

1. Substrate:

Increase in respiration activity of cells by assimilation of substrate (glucose) is monitor-able by oxygen electrode.

Based on this microbial electrode sensor for glucose have been constructed (Fig 7.2) using immobilized whole cells that utilize mainly glucose and oxygen.

ADVERTISEMENTS:

Components of the electrode system: It consists of the following:

a. Immobilized whole cells of Pseudomonas fluoresces.

b. Oxygen electrode.

c. The bacteria-membrane in contact with O2 electrode is tightly secured with rubber O-rings.

ADVERTISEMENTS:

Working: In working of microbial glucose sensor the following steps are involved:

i. The sensor assembly is inserted into a glucose sample solution.

ii. The solution is saturated with dissolved oxygen by stirring at fermentation temperature 30° ± 1 °C prior to insertion of electrode.

iii. The bacteria in the membrane begin to utilize glucose and oxygen in sample solution and current of the sensor markedly decreased with time until a steady state is reached.

iv. The current is measured by a milliammeter and signal is displayed on the recorder as response curve. (Fig. 7.2 b and c).

v. The steady current is attained within 10 mins at 30°C. It is dependent on the concentration of glucose (Fig 7.2 b).

vi. When the sensor is removed from the sample and placed in a solution free from glucose the current of the microbial sensor gradually increases and returns to the initial level within 15 minutes at 30° ± 1°C (Fig.7.2 b).

Advantages:

ADVERTISEMENTS:

Advantages of the biosensor are given below:

i. It can be used for continuous determination of glucose in molasses broth.

ii. Reusable several times.

iii. No response to amino-acids.

ADVERTISEMENTS:

iv. Satisfactory sensitivity

Disadvantage:

It responded slightly to fructose, galactose, mannose and saccharose.

2. Cell population:

(i) Direct Method: Principle:

It was found that bacterial oxidation occurred directly on the surface of the anode and a current was generated. This electrochemical system has been applied to determine microbial cell populations.

ADVERTISEMENTS:

Electrode system:

It is composed of two similar electrodes as shown in the Fig. 7.3 namely

(a) The determination electrode

(b) The reference electrode.

Each electrode is composed of platinum anode (pt) and the silver peroxide (Ag2O2) cathode. Phosphate buffer (0.1M, pH 7.0) is used as catholyte. An anion exchange membrane is used as a separator. The current is measured by a milliammeter and signal is displayed on a recorder. Working: Both the electrodes are inserted into a culture broth. The current of the determination electrode (I1) resulted from microbial oxidation and of electro active substances is obtained. The current of the reference electrode (I2) is due to oxidation of electro-active substances only because cells could not penetrate through cellulose dialysis membrane. Thus, the current difference between the two electrodes is as below.

∆I= I1 – I2 (7.23)

This ∆I is proportional to the number of microbial cells in the broth (Fig. 7.4). So one can write

∆I = KN (7.24)

Where N is the number of cells and K is a constant. Fig 7.4 provides calibration curves for microbial cell population. However, the response time of the electrode system varies with temperature and pH as illustrated in Figs. 7.5 a-d for Saccharomyces cerevisiae which was centrifuged at 8000 x g for 10 minutes to be used in calibration.

(ii) Indirect Method:

An indirect method of electrometric detection and counting of E. coli in the presence of a reducible coenzyme, lipoic acid (LA) has been reported. In this method reduction of LA by bacteria coupled to oxygen consumption during uptake of glucose has been followed potentiometrically with a pair of gold and reference electrodes in a minimal culture medium.

From the variation of potential as a function of time, a theoretical relation could be derived between inoculum size and the time preceding the appearance of the wave. Making reasonable assumptions the theoretical minimum lag time, t1 (TMLT) was developed from the law of cell growth and consequent dissolved oxygen (DO) consumption in the following form.

In this relation Q’m is maximum specific oxygen uptake rate, (O2)0 is the DO at time t = 0, x0 is the cell concentration and tg is generation time. This potentiometric method relies on the choice of an adequate culture medium (minimal glucose medium, with or without yeast extract) and a natural oxidation-reduction indicator (LA) which is reduced without degradation during bacterial growth.

3. Product:

(i) Alcohol Biosensor:

On line measurement of ethyl alcohol or methanol in 1. ethanol/methanol fermentation and 2. yeast cultivation is very much required to:

(i) Minimize product inhibition and

ADVERTISEMENTS:

(ii) Increase yield.

In cultivation of microorganisms using methanol or ethanol as carbon source, its concentration must be maintained at the optimal level to overcome product inhibition.

Principle:

As many microorganisms can use alcohols as carbon source, its concentration can be determined from the respiration activity of cells. The respiration activity is directly measured by oxygen electrode. It has thus been possible to construct microbial sensor for alcohols using immobilized microorganisms and oxygen electrode.

Biosensor system:

It consists of the following components:

(i) Immobilized yeast ( e.g. AJ 3993) or bacteria ( e.g. Trichosporon brassicae, CBS 6382),

(ii) A gas permeable membrane (teflon) and

(iii) An oxygen electrode.

Porous membrane retaining microbial cells is fixed on the surface of the teflon membrane of the electrode. So, the cells are trapped between the two membranes. Also, a gas permeable membrane is placed on the surface of the electrode and covered with nylon net. These membranes were fastened with rubber o-rings. The steady state current obtained depended on the concentration of ethanol/methanol. The response time is within 10 mins at 30°C.

Modification:

Since steady state method required long response time, a pulse method was used for the determination. The assay can be done within 6 mins. by this method. The total time required by steady state method was 30 mins while it took only 15 mins by pulse method. The current difference was reproducible within ± 6% using 16.5 mgl–1 ethanol. The standard deviation was 0.5 mgl-1 in 40 experiments. For sensing bio-products, oxygen probe biosensors having characteristics as given in Table 7.3 have been developed in more recent years.

4. Bioprocess effluent BOD:

(i) BOD Sensor Electrode:

Scheme of BOD sensor microbial electrode consists of the following components (Fig. 7.6.a):

1. Bacteria-collagen membrane (50 pm thickness)

2. Teflon membrane (27pm)

4. Electrolyte (KOH)

5. Lead (Pb)-anode

6. O-ring

Its measuring circuit components consist of the following items (Fig. 7.6.b):

1. Microbial electrode,

2. Recorder,

3. Amplifier,

4. Air,

5. Magnetic stirrer,

6. O-ring.

Response curves of the sensor in 60 ml standard solution containing 0.1M Phosphate buffer (pH 7.0) and varying BOD sample between 2.5% to 10% at 30°C is shown in Fig.7.6. c. Current (µA)-Concentration (%) and BOD (ppm) relationship of this BOD sensor electrode is shown in Fig. 7.6.d. It indicates that when BOD < 22 ppm i.e. in the region of concentration <10% can be estimated by this electrode. A standard relation of current-BOD in waste water is shown in Fig. 7.6d. Good reusability pattern of BOD sensor electrode given in the figure shows reliability of its response.

Reusability:

The current of the microbial BOD sensor is determined after it had been immersed in the standard solution. It is repeated three times per day. The repeated use shows response as given in Fig. 7.7.

(ii) Biofuel Cell BOD Sensor:

As shown in Fig. 7.8 the sensor components are numbered. The sensor was calibrated using 200 ml 0.1 M phosphate buffer with different concentration of glucose (2.5 – 400 gm/ml) and gluconic acid. The electrode output in μA is obtained after 40 mins.

From the above section it is clear that biosensor technology is advancing very fast. The area of patterning self assembled monolayers (SAMS) using micro-contact printing (pep) is an example of new technology for novel biosensors.

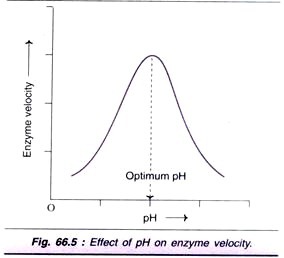

5. Enzymic biosensors:

The development of enzymic biosensors as integral component of process biotechnology is progressing rapidly. These biosensors are being used to measure either substrate or bio-product concentrations in samples. Two examples of these biosensors are glucose oxidase and urease immobilized on the electrode membranes. Another important enzymic biosensor, very useful in food industry is monosamine oxidase electrode sensor. It is used in freshness testing of meat.

Various compounds such as amines, carboxylates, aldehydes, ammonia and carbon dioxide are produced in the meat putrefaction process. The conventional method of testing meat freshness is the measurement of volatile basic nitrogen in meats. However, this method is complicated involving many operations. This complicated method has been replaced by determination of monosamines using biosensor.

Monosamine oxidase (monooxygen oxidoreductase EC 1.4.3.4 from Aspergilus niger and beef plasma) has been immobilized in a collagen membrane. The biosensor, consisting of a monosamine oxidase-collagen membrane (10 units) and an oxygen electrode, could be developed and used to determine monosamines in meat and meat products by determining oxidation of monosamines with dissolved oxygen in the presence of monoamine oxidase as per following reaction

The principle of this bioassay is based on monitoring the decrease in dissolved oxygen resulting from the above enzymatic reaction in the presence of monosamines and the oxygen electrode determines dissolved oxygen. A few of the oxygen probe immobilized enzyme (IE) biosensors have been listed in Table 7.3.